View of two of the raised treads (grousers) on the left middle wheel of the Curiosity rover which recently broke, including the one seen partially detached at the top of the wheel. NASA has now developed a new algorithm that adjusts the rover’s wheels speed depending on the rocks it’s climbing, to minimize wear on the wheels. Photo Credit: NASA/JPL-Caltech/MSSS

A true marvel of engineering, NASA’s Curiosity Rover has been exploring Gale Crater on Mars now for nearly five years, revealing different eras of the planet’s geological history in the various rocks and terrain it covers while learning to locate environments that can, or did, or could have supported life.

The question it set out to answer—was Mars ever habitable at some point in its history—was answered with a resounding yes several years ago by the rover, when it drilled into rocks and discovered key chemical ingredients for life. But in that time, its solid aluminum wheels have taken quite a beating.

A “scarecrow” rover at NASA’s JPL drives over a sensor while testing a new driving algorithm. Engineers created the algorithm to reduce wheel wear on the Mars Curiosity rover. Credits: NASA/JPL-Caltech

So far, the rover has driven over 10 miles (16 kilometers) since landing, and in that time everything from small dents and holes, to breaks in the raised treads, has occurred due to jagged rocky terrain and Curiosity’s tendency to ‘pop wheelies’ when a climbing wheel clears the surface of a rock and free-spins.

When that happens, it increases forces on the wheels that are still in contact with ground, causing damage over time. Additionally, on level ground, all of Curiosity’s wheels turn at the same speed, but when a wheel goes on inclines over uneven terrain the wheels behind/front of it to start slipping, which is especially problematic when driving over sharp rocks.

Concerns over such issues forced engineers at the Jet Propulsion Laboratory (JPL) to start looking into it years ago, not long after the Rover arrived at Mars and began driving, and have since come up with a way to minimize wear on the wheels with a new driving algorithm “traction control software“.

“During testing at JPL, the wheels were driven over a six-inch (15-centimeter) force torque sensor on flat terrain,” says NASA. “Leading wheels experienced a 20 percent load reduction, while middle wheels experienced an 11 percent load reduction.”

After 18 months of testing, it was uploaded to the rover on Mars in March, and approved for use in early June after several additional successful tests on the Red Planet itself.

“The wheel wear has been cause for concern, and although we estimate they have years of life still in them, we do want to reduce that wear whenever possible to extend the life of the wheels,” said Art Rankin of JPL, the test team lead for the new traction control software developed by Jeff Biesiadecki and Olivier Toupet.

Each of Curiosity’s six wheels is about 20 inches (50 centimeters) in diameter and 16 inches (40 centimeters) wide.

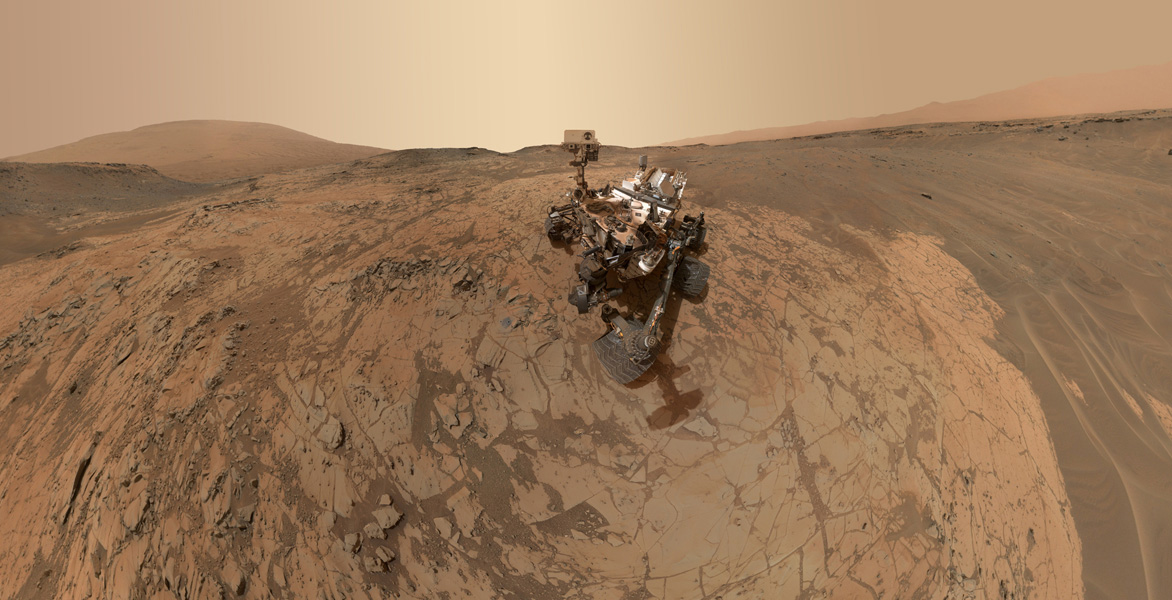

This self-portrait of Curiosity was taken at the “Mojave” site, where its drill collected the mission’s second taste of Mount Sharp. The scene combines dozens of images taken during January 2015 by the MAHLI camera at the end of the rover’s robotic arm.

Image Credit: NASA/JPL-Caltech/MSSS

“When this happens, the wheels in front pull the trailing wheels into rocks; the wheels behind push the leading wheels into rocks,” noted NASA on June 29. “In either case, the climbing wheel can end up experiencing higher forces, leading to cracks and punctures. The treads on each of Curiosity’s six wheels, called grousers, are designed for climbing rocks. But the spaces between them are more at risk.”

“If it’s a pointed rock, it’s more likely to penetrate the skin between the wheel grousers,” said Rankin.

The algorithm uses real time data to measure changes with the rover’s suspension system to figure out the contact points of each wheel, and then calculates the necessary speed to avoid slipping.

And if Curiosity tries popping anymore wheelies, it will adjust the speeds of the other wheels until the rising wheel is back on the ground.

Quelle: AS