Staring up High Bay 3 in the Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center in Florida, the 10 work platform levels that will surround NASA’s Space Launch System rocket and Orion spacecraft to allow access during processing for missions. Photo Credit: NASA / Frank Michaux

The final of 10 giant steel work platforms to support launch preparations of NASA’s Space Launch System (SLS) rocket and Orion crew capsule is now installed in Kennedy Space Center’s (KSC) iconic 525-foot-tall Vehicle Assembly Building (VAB), marking a significant milestone in the ongoing evolution of NASA’s spaceport and the historic facility previously used to process all 135 space shuttle launches and the Saturn-V rockets which sent men to the Moon during the Apollo program.

All space shuttle work platforms in High Bay 3 were removed to make way for a new SLS platform system in 2013, and work in High Bay 3 has been underway ever since to receive the 20 platform halves which make up all 10 SLS platforms. The platforms are critical in giving engineers access to the 322-foot-tall rocket and spacecraft prior to being rolled out to Launch Complex 39B a few miles away, where crews will launch on missions to the Moon and beyond over the coming years.

Continue reading PHOTOS: Final SLS Work Platform Installed in KSC’s Vehicle Assembly Building

Quelle: AS

-

Update: 29.01.2017

.

Model of giant SLS rocket gets wind tunnel-tested by NASA Langley

Late next year, the most powerful rocket ever built is set to launch from U.S. soil, boosting an unmanned space capsule farther than humans have gone since the Apollo program — off to circle the moon and back home again.

But before that super-rocket — called the Space Launch System, or SLS — can attempt that milestone, it must first pass muster with NASA.

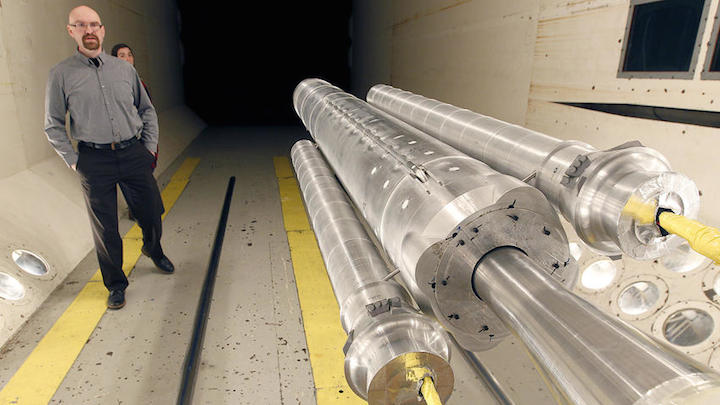

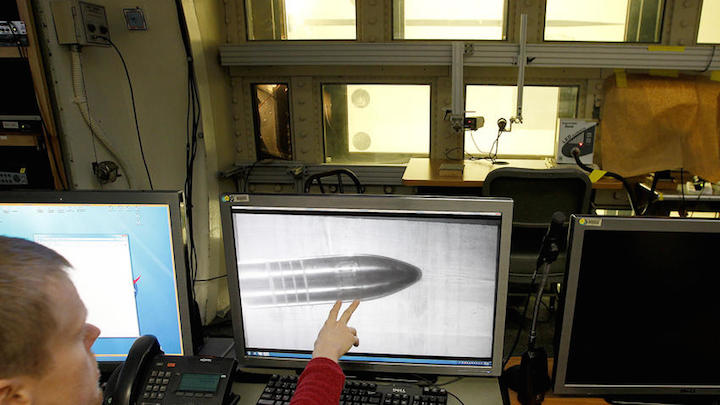

So for the past several months, scientists and engineers from NASA Langley Research Center in Hampton have been putting a 10-foot model of the 364-foot SLS through its paces in the Transonic Dynamics Tunnel, a NASA wind tunnel located at Langley Air Force Base.

The slim, silver rocket model has been pitched and rolled, blasted with chilly refrigerant at speeds up to 900 miles an hour, all to mimic the extreme shuddering and buffeting the real thing will endure as it breaknecks up through the atmosphere.

"One of the most challenging aerodynamic environments that we encounter is as we approach the speed of sound," said research engineer Martin Sekula. "The shock (waves) are moving around on the vehicle, vortices and eddies are being shed off of different parts of the vehicle, and they can impinge on other parts of the rocket. And if these loads are incredibly violent — back in the '60s, they had some launch vehicles that were lost because of this buffeting."

The model is stuffed with about half a mile of wiring for hundreds of sensors embedded just under its skin, many as tiny as a match head. Some are so fragile, Sekula said, "you look at them funny, they break."

But the data they collect help to hone the vehicle that is designed to boost humans on deep-space missions long into the future — to an asteroid, to Mars and beyond.

The first test run at this tunnel last year, for instance, identified vortices that were shedding and creating huge loads on the model, said Sekula.

So they set to work with computational fluid dynamics colleagues and, with an assist from a NASA supercomputer, identified the problem and a good fix.

The rocket is designed as three different configurations, each achieved by swapping out the nose cone on the 200-foot rocket core, depending on whether it is carrying people or payload.

"So it's either got a crew capsule or it's got this cargo configuration where we're carrying equipment out to space to build whatever it is we need to do to get to Mars, to get us on our journey," said Amber Favaregh, deputy lead for the Langley SLS aerodynamics team. "These changes can make a big impact."

The rockets are intended as the new workhorses for NASA's deep-space missions, capable of carrying up to 105 metric tons and ranging in height from 322 feet to 364 feet. That's just a tad taller than the mighty Saturn V, at 363 feet. The Saturn V was built to launch astronauts to the moon and last flew in 1973.

NASA is already working on a fourth configuration that would stand at 365 feet and carry up to 130 metric tons.

This latest buffet test was the third and final entry for the SLS at the wind tunnel. NASA Langley says more versions and configurations will be tested at other NASA facilities over the next year.

"For us, it's been very exciting," said Sekula. "For me, it's awe-inspiring.

"I went down to see a (space) shuttle launch a number of years ago. It was my first launch ever, and it really struck me emotionally. I did not expect it. To see human beings who are leaving our planet. And whenever we're doing this kind of work, I'm always kind of reminded of that moment. It sends chills down my spine that I'm helping to take our species and help them leave the planet. To go to the moon. Maybe on a journey to Mars."

The SLS could be carrying a crew as early as 2021, sending them off to loop around the moon. Such responsibility isn't taken lightly, said Favaregh.

"You don't know what you don't know until something happens," she said. "You definitely just have to prepare, and do your very best to prepare."

When the SLS program first began, the scientists said, meetings would often begin with a brief moment of silence for those astronauts lost in the line of duty.

"Basically, bringing to mind that this is not just, 'hey, we're going to launch a rocket,'" Sekula said. "We're potentially affecting families and our co-workers. This is serious business. And we take it very, very seriously. Because it's dangerous.

"I mean, we're asking people to sit on top of a 300-foot-tall fuel tank, and we're gonna just ignite a match on one end and see what happens? No, we want to be careful. To bring these people home. It kind of brings you back down to Earth, knowing that this is extremely dangerous work, and these people are putting their faith in us."

NASA is developing the SLS with industry partners including Dulles-based Orbital ATK; the Boeing Company, based in Chicago; Aerojet Rocketdyne of Sacramento, Calif.; and Teledyne Brown Engineering of Huntsville, Ala.

Quelle: Daily Press

-

Update: 31.01.2017

.

NASA has successfully completed the exploration upper stage (EUS) preliminary design review for the powerful Space Launch System rocket. The detailed assessment is a big step forward in being ready for more capable human and robotic missions to deep space, including the first crewed flight of SLS and NASA's Orion spacecraft in 2021.

"To send humans and even more cargo farther away from Earth than ever before, NASA decided to add a more powerful upper stage -- the upper part of the rocket that continues to operate after launch and ascent," said Kent Chojnacki, EUS team lead and preliminary design review manager.

"With the completion of this review, our teams will start developing components and materials for the EUS, and build up tooling," he added. "Full-scale manufacturing will begin after the critical design phase is completed." Critical design review is the next programmatic milestone that will provide a final look at the design and development of the EUS before beginning full-scale fabrication.

Starting with that first crewed mission, future configurations of SLS will include the larger exploration upper stage and use four RL10C-3 engines. The EUS will replace the interim cryogenic propulsion stage that will be used on the initial configuration of SLS for the first, uncrewed flight with Orion. The EUS will use an 8.4-meter diameter liquid hydrogen tank and a 5.5-meter diameter liquid oxygen tank. A new universal stage adapter will connect the EUS to the Orion spacecraft, and be capable of carrying large co-manifested payloads, such as a habitat.

The preliminary design review kicked off Nov. 30, 2016, with approximately 500 experts from across NASA and industry assessing more than 320 items on the EUS, including documents and data. This review had a new "techie" touch to it with the incorporation of virtual reality glasses, which gave teams enhanced visuals of how the EUS is put together and a broader perspective on the size of the hardware. The preliminary design review board was completed Jan. 19, with the board voting unanimously that the EUS is ready to move to the critical design phase.

"I couldn’t be prouder of the SLS Stages team completing this review," said SLS Program Manager John Honeycutt. "We continue to make progress on hardware for SLS’s first flight, while also working on the next-generation rocket that will take astronauts to deep-space destinations, like Mars."

The powerful stage will be built at NASA's Michoud Assembly Facility in New Orleans. Massive welding machines, like the Vertical Assembly Center, currently building the SLS core stage, also will help build the EUS liquid hydrogen tank. New tooling and assembly areas will be put in place to manufacture the liquid oxygen tank.

Once built, the EUS structural test article will undergo qualification testing at NASA's Marshall Space Flight Center in Huntsville, Alabama, to ensure the hardware can withstand the incredible stresses of launch. "Green run" testing on the first flight article will be done at NASA's Stennis Space Center near Bay St. Louis, Mississippi. For the test, the EUS and RL10 engines will fire up together for the first time before being sent to Kennedy Space Center in Florida for the 2021 launch.

By Linda Herridge

NASA's John F. Kennedy Space Center

NASA reached a key milestone in the Vehicle Assembly Building (VAB) at the agency's Kennedy Space Center in Florida. A year of platform installations came to conclusion in January as the final work platform, A north, was lifted, installed and secured recently on its rail beam on the north wall of High Bay 3 inside the iconic facility.

The installation of the final topmost level completes the 10 levels of work platforms, 20 platforms halves altogether, that will surround NASA's Space Launch System (SLS) rocket and the Orion spacecraft and allow access during processing for missions, including the first uncrewed flight test of Orion atop the SLS rocket.

"Just a year ago, we were meeting the challenges of getting the first half of the first platform installed," said Mike Bolger, Ground Systems Development and Operations (GSDO) Program manager, "It's a great testament to the creativity, persistence and hard work of the team, and it's a terrific indicator that GSDO is on track to process the SLS and Orion flight hardware for the first test mission."

The A platforms will provide access to the Orion spacecraft's Launch Abort System (LAS) for Orion lifting sling removal and installation of the closeout panels. LAS Antenna Testing also is performed on this level.

The platforms were mated with two, 60,000-pound rail beam assemblies that allow the platforms to move towards and away from the vehicle, as well as tie the entire system to the VAB structure. Each platform will ride on four Hillman roller systems on each side — much like how a kitchen drawer glides in and out. The process to lift and install each of the platforms takes about four hours. Each platform weighs more than 300,000 pounds, and measures about 38 feet long and close to 62 feet wide.

"I am very proud of the amount of work that the team accomplished. I am also humbled to have been able to lead this group of amazing people who have been able to complete this very complex and challenging project," said Jose Perez Morales, GSDO VAB Element senior project manager. "I am very pleased with all the work performed by the NASA and contractor team."

Engineers began installation of the first halves, the K-level platforms, about a year ago, followed by the J, H and G platforms. In July 2016, platform installation reached the halfway point, with the fifth of ten levels of platforms, the F-level, completed.

The remaining platforms installed are E, D, C, B and A. Each of the platform levels is strategically located to allow technicians and engineer’s access to different systems on the rocket, Orion spacecraft and the Launch Abort System during processing and stacking operations on the mobile launcher.

"This is a huge day for us," said Darrell Foster, GSDO Project Management Division chief. "We cherish these milestones. We're all working toward launch day success."

GSDO, with support from the center's Engineering Directorate, is overseeing upgrades to the VAB, including the installation of the work platforms.

NASA awarded a contract to modify High Bay 3 to the Hensel Phelps Construction Co. of Greeley, Colorado, in March 2014. Hensel Phelps, along with its subcontractors, Institutional Services Contract, Engineering Services Contract, and Test and Operation Support Contractor, supported crane operations, lifting, installation and initial inspection of each of the platforms.

NASA to study launching astronauts on first SLS mission

Updated at 2 p.m. Eastern with Lockheed Martin statement.

WASHINGTON — NASA plans to study putting astronauts on the first launch of its Space Launch System heavy-lift rocket, a move that could introduce new delays and other complications into the vehicle’s development.

NASA Acting Administrator Robert Lightfoot, in a speech at the Space Launch System/Orion Suppliers Conference here Feb. 15, and a memo emailed at the same time to the agency’s workforce, said he had directed Bill Gerstenmaier, NASA associate administrator for human exploration and operations, to begin a study on the feasibility of putting a crew on the first SLS mission, known as Exploration Mission 1 (EM-1).

“The study will examine the opportunities it could present to accelerate the effort of the first crewed flight and what it would take to accomplish that first step of pushing humans farther into space,” NASA spokesman Bob Jacobs said in a statement to SpaceNews confirming the planned study.

Current plans call for the EM-1 mission to launch in late 2018 without a crew. The first crewed flight would be EM-2, which NASA is planning to launch in 2021. However, an assessment in 2015 performed as Orion reached a development milestone known as Key Decision Point C indicated that there was a 70 percent chance the EM-2 mission would launch no later than April 2023.

Lightfoot, in the memo, said the study will examine the technical and schedule issues of flying a crew on EM-1. “I know the challenges associated with such a proposition, like reviewing the technical feasibility, additional resources needed,” he wrote, “and clearly the extra work would require a different launch date.”

Lightfoot didn’t discuss the specific challenges, but they are likely to involve both issues with the Orion spacecraft and SLS vehicle. NASA did not plan to have a full life support system in the Orion spacecraft for the EM-1 mission as it would not have a crew on board. Last year, the agency said it was considering shortening the EM-2 mission since it would be the first Orion flight with the complete life support system.

“Lockheed Martin will support NASA on a study to determine the feasibility of flying a crew on Exploration Mission 1,” said Allison Miller, a spokeswoman for Orion prime contractor Lockheed Martin, in a Feb. 15 statement. “We’ll look at accelerating remaining crew system designs, as well as potential technical and schedule challenges and how to mitigate them.”

The SLS that will be used on EM-1 will use an upper stage derived from the Delta 4, known as the Interim Cryogenic Propulsion Stage (ICPS). NASA plans to replace it on EM-2 and future SLS missions with the more powerful Exploration Upper Stage (EUS), which would be human-rated for crewed missions.

NASA stopped work on human-rating the ICPS a year ago, following direction from Congress in the report accompanying the fiscal year 2016 appropriations bill. Congress has pushed NASA to accelerate work on the EUS, allocating additional funding for it, so that it would be ready for EM-2. NASA announced in January that EUS had passed its preliminary design review, keeping the stage on track for launch in 2021 on the EM-2 mission.

That work, as Lightfoot suggested in his memo, would likely delay the EM-1 launch from its current estimated launch window of September to November 2018. Industry sources said they believe addressing the various issues would delay the mission to 2019 or 2020. That would still be sooner than current NASA schedules for EM-2.

Lightfoot, in the memo, also addressed broader concerns about NASA’s future direction. “From my interactions with the transition team, NASA is clearly a priority for the President and his administration,” he wrote, adding that when he received information from the administration about its plans for the agency, he would share it with employees.

“There has been a lot of speculation in the public discourse about NASA being pulled in two directions – what has come before and what we want to do now. At NASA, this is an ‘and’ proposition, not an ‘or,’” he added near the end of the memo. “We must work with everyone to secure our leadership in space – and we will.”

Quelle: SN

-

Update: 24.02.2017

.

NASA is inviting media to attend a test of the Orion spacecraft’s parachutes on Wednesday, March 8, at the U.S. Army’s Yuma Proving Ground in Arizona. Orion is scheduled for its second airdrop test, in a series of eight, to qualify the parachute system for crewed flights.

Media will have the opportunity to interview Orion engineers, see the model up close and view the test from the drop zone. To attend, media must contact Laura Rochon at laura.a.rochon@nasa.gov by 1 p.m. EDT on Thursday, March 2.

During the test, an engineering model of the Orion spacecraft will be dropped from a C-17 aircraft flying at an altitude of 25,000 feet. This test will simulate a descent sequence astronauts might experience if they have to abort a mission after liftoff. The test sequence begins under simulated abort conditions when Orion is traveling at the relatively slow speed of about 130 mph, as compared to 310 mph for a normal end of mission Earth re-entry.

The team will focus on two primary aspects of system performance in this scenario: deployment of Orion’s two drogue parachutes at low speeds, and deployment of its three main parachutes in preparation for landing.

Orion’s parachutes are critical to the safe return of the spacecraft to Earth, whether during an abort sequence or at the end of a successful deep space mission. They help stabilize and slow the crew module to about 20 mph, enabling a safe splashdown in the ocean.

Orion is built to take astronauts farther into the solar system than ever before. The spacecraft will carry astronauts to space, provide emergency abort capabilities, sustain the crew during their mission and provide safe re-entry through Earth’s atmosphere.

Quelle: NASA

---

Space Launch System engine test brings out a rainbow

NASA and nature collide again when a test of a rocket engine that will help power the Space Launch System to space was graced by a rainbow.

The RS-25 test was a first for 2017, held at Stennis Space Center in Mississippi. When the Space Launch System eventually lifts the Orion capsule into space, four RS-25 engines along with two solid rocket boosters will be providing the power.

This test was using a development engine, no. 528, and the test that lasted 380 seconds allowed engineers to minotor various conditions.

If the engine looks familiar, it's because the engines being used on the first four slate Space Launch System flights are repurposed Space Shuttle main engines.

Also at Stennis is the preparation of the B-2 Test Stand that will be used to test the core stage for the next Space Launch System flight with the Orion capsule, which is Exploration Mission-1, slated for late 2018. That test will have the flight stage on stand while firing four RS-25 engines simultaneously.