9.02.2024

ArianeGroup prepares to ship Ariane 6 maiden flight rocket to Kourou

The combined Ariane 6 launcher task force, consisting of ESA, CNES, and ArianeGroup, has reported on the progress of Ariane 6, the steps to launch, and the beginning of stage shipments to the launch site.

The Canopée ship, which Ariane and ESA use to transport the massive rocket, will collect the first and second stages from France and Germany, respectively. ESA reports that the first flight remains on track, targeting a launch window between June 15 and July 31, 2024.

The first flight will feature several small rideshare payloads on top of the Ariane 62. These include the SpaceCase technology demonstrator, the small 1U ISTSAT CubeSat, and many more.

“We will be sharing more about the payloads in February… There will be CubeSats and some payloads from NASA,” ArianeGroup told NSF.

During a factory visit of both the second stage facility in Bremen, Germany, and the first stage facility in Les Mureaux, France, NSF was able to interview high-level officials of the Ariane program as well as ESA Acting Director of Space Transportation Toni Tolker-Nielsen.

The first stage

The first stage of the Ariane 6 rocket is assembled in Les Mureaux, close to Paris. The facility to construct it is not far away from the Ariane 5’s vertical assembly building. In contrast to its predecessor rocket, Ariane 6 is assembled horizontally.

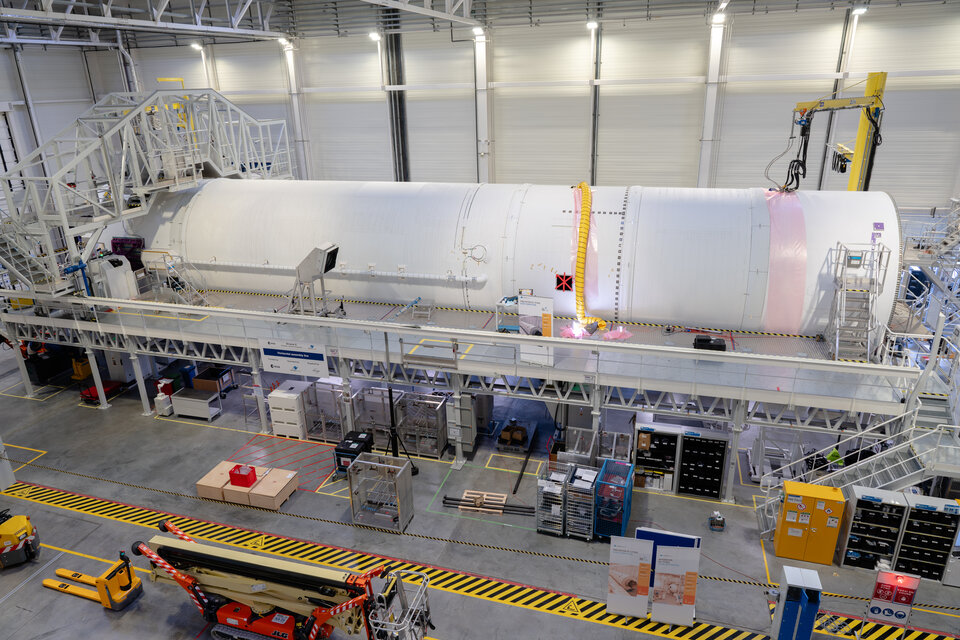

During the time of the visit, the factory already featured the fully assembled first stage for flight one. The Vulcain 2.1 engine was already integrated into the bottom of the rocket, and the transport container for the Canopée ship was prepared outside of the factory.

The factory also featured a hydrogen tank for flight three in testing, as well as parts for flight four and beyond. ArianeGroup confirmed to NASASpaceflight that six rockets are currently in work on the factory floor.

Main stage of Ariane 6 Flight Model 1 in ArianeGroup’s integration hall in Les Mureaux. (Credit: ArianeSpace)

Down the line, the goal of the factory is to support twelve flights a year. This cadence is shared by the second stage facility and is dictated by the turnaround time of Canopée, which needs roughly 28 days for a full trip to the Guyana Space Center and back.

To date, Ariane 6 has roughly 30 launch contracts signed. These mostly consist of Amazon’s Project Kuiper, but also feature missions such as Galileo and the PLATO exoplanet telescope.

Ariane 6 features the Vulcain 2.1 hydrolox engine on its first stage, which produces 1,370 kN of thrust. It is the successor to the Vulcain 2.0, which was used on Ariane 5. Down the line, potential upgrades to Ariane 6, such as a change to the Prometheus methalox engine, are possible — although this is more likely on the future Ariane Next vehicle.

A prototype Prometheus engine is fired in Vernon, France. (Credit: ArianeGroup)

Prometheus is the “Precursor Reusable Oxygen Methane cost Effective propulsion System”, which is developed by ArianeGroup and ESA for Ariane Next. This methalox engine is part of a future engine development plan for ESA. It is also used on their Themis vertical takeoff and vertical landing prototype, in which ESA explores the idea of developing reusable rocket technology.

In the future, the Prometheus engine might be on the upgrade path for Ariane 6. Frank Huiban, Director of Civil Programs at ArianeGroup, said, “[When] working on space programs, you have to consider several things in parallel. You can not only work on your current development but also need to prepare the following one. This is what we do with Prometheus, Themis, and other projects we run together with ESA.

“The purpose is to prepare the key bricks for the next generation of European space transportation. Prometheus is part of that. It is not featured on Ariane 6 today, but it will be featured on other launch systems, developed by either ArianeGroup or other players. We will offer the engine to whoever will be interested to use it in systems.”

Regarding the fact that the first launch is a rideshare and the implications from that for the future of Ariane 6, he added, “For the inaugural flight, Ariane 6 will fly with more than 10 experiments and missions. It was a choice made together with ESA to invite all innovators to propose payloads for Ariane 6. From the very beginning, we start with this collective flight. In the future, we will have the possibility to group a large number of small missions to take the opportunity of one heavy lift to space.”

The second stage

For the second stage of Ariane 6, the company uses their facility in Bremen, Germany. The factory also features multiple stages in production, and the flight one stage already has its Vinci engine integrated. New for Ariane 6, compared to Ariane 5, is the ability to relight the engine for deep space missions.

Previously, Ariane 5 could only ignite its upper stage once, which allowed for missions to be sent to a geostationary transfer orbit (GTO). With this relight capability, Ariane 6 can now launch directly to geostationary orbit (GEO), using a relight a few hours into the mission. Overall, the current version of Ariane 6 can launch up to five metric tons to GEO.

The upper stage of Ariane 6 flight one model in ArianeGroup’s integration hall in Bremen. (Credit: ArianeGroup)

“We already had the experience from the cryogenic upper stage of Ariane 5, but that stage was just a one-shot upper stage. You ignite it, you empty the tanks, it finishes, and that’s it. With Ariane 6, we wanted another feature. […] And this reignition of a cryogenic upper stage is the challenge we had to solve,” ArianeGroup told NSF.

The re-ignition of the stage is not done using chemicals but is instead driven by an electrical spark that ignites a mixture of hydrogen and oxygen gas, which then creates a flame and ignites the main chamber.

Aside from the addition of reignition, Arianespace also changed the material of the nozzle extension to a carbon ceramic.

Regarding the testing process, ArianeGroup said to NSF, “We are usually starting with electrical testing at the stages here, checking that the harness and connections are properly done. If that one is clean, we are going to a fluid test. This is where we pressurize the stage, check for leaks, and check the valve switching. We are verifying all the functions it has to perform in space.”

The aft end of the Ariane 6 second stage. (Credit: ArianeGroup)

Another major change in the upper stage is the addition of the auxiliary power unit (APU). Its main role is to pressurize the tanks during flight and allow for longer coasting times. The device will also be used to deorbit or passivize the second stage after its primary mission. The system was tested at the DLR site in Lampoldshausen, Germany.

“We take guidelines very seriously to deorbit our stages, together with ESA, and this is why Ariane 6 fulfills these deorbit requirements, while other nations ignore the regulations,” Ariane told NSF.

Regarding the production of the Ariane 6 second stage, ArianeGroup added, “For this year, we are probably expecting two more stages, since we are just starting the ramp-up. The whole logistics chain is just starting. The team itself would be ready for more… We are limited by the production of the parts. We could produce more stages… If another ramp-up in the future is needed, we can support even more.”

The boosters

The P120 rocket boosters are made by Avio in Italy. They are not only used for Ariane 6 but also for the VEGA-C/E. Ariane 6 comes with the ability to feature either two or four of the P120 boosters. The maiden flight will feature two, which is indicated by the “2” in “Ariane 62.”

An Ariane 6 solid rocket booster. (Credit: ESA-CNES)

Down the line, the plan is to upgrade the boosters to the P120C+. This will extend the length of the boosters, and feature 14 tonnes of additional propellant. The Amazon project Kuiper missions plan to utilize the upgraded booster after the second Kuiper flight.

Transport and the path to launch

With both stages now concluding their assembly and testing, the next step will be their shipment onboard Canopée. The hybrid ship, powered by both wind and fuel, was developed to transport the rocket. This approach was chosen to reduce the carbon emissions of the Ariane 6 project.

“With the ramp-up, the boat is designed to be always on rotation to support twelve flights a year.”

The ship will load both the first and second stages, as well as the booster casings for flights. Once it arrives at the Guiana Space Center in Kourou, the rocket will be fully assembled horizontally, before being moved to the launch pad.

After integration, Ariane 6 will not perform any more integrated testing, such as a static fire on the pad, as the qualification test from the certification pathfinder was deemed sufficient.

The Ariane 6 pathfinder upper stage being loaded into its transport container. (Credit: ArianeGroup)

Regarding pre-flight tests, Tolker-Nielsen said, “We retired a huge amount of risks last year with the combined testing in Corou by performing tanking and firing tests. This went well. We also did important testing of the upper stage in Lampoldshausen, where we performed full flight simulations. We are very confident now, with shipping the flight hardware, and we are undertaking a qualification review. […] This will confirm that we can fly all of this safely.”

For the first flight, ESA will operate the launch as the primary contractor. For later flights, Arianespace will take over the operation of the vehicle. For flight one, Arianespace and CNES officials are still involved in the operation of the rocket.

Regarding this, Tolker-Nielsen said, “It has always been like that. It is a flight under ESA responsibility, we have bought this as part of our development program, so we are responsible for this first flight.”

The future of launching at ESA

Aside from Ariane 6, ESA’s Acting Director of Space Transportation Toni Tolker-Nielsen also talked with NSF about the future of launch vehicles at ESA.

NSF asked Tolker-Nielsen how his optimal European launch market looks in the future. “Tomorrow we will have Ariane 6 and Vega-C. That will ensure independent access to space from Europe. At the same time, we have all these micro launchers developed all over Europe. In France, in Germany, in Spain, in the UK. We would like to force them to grow and introduce more competition to Europe. We believe this is necessary for the competitiveness of the sector in the future.

Toni Tolker-Nielsen, Acting Director of Space Transportation for ESA. (Credit: ESA)

Regarding the topic of reusability, he said, “For the launchers that will come after Ariane 6 and Vega-C, they will be reusable. That is because of two reasons: I believe the market, both institutional and commercial, will grow, which means we need an increased cadence. And with that, it becomes economically viable to have reusability. The other reason is sustainability. We can not throw away stages like that in the future. For these two reasons, I am convinced that the next generation will be reusable launchers.”

(Lead Image: The first stage for Ariane 6 flight model one in ArianeGroup’s integration hall in Les Mureaux. Credit: ArianeGroup)

Quelle: NSF

----

Update: 13.02.2024

.

First Ariane 6 flight model ships to Europe’s Spaceport

The stages that make up the central core of Europe’s new rocket, Ariane 6, have left mainland Europe and are heading towards Europe’s spaceport in French Guiana. Shipping across the Atlantic, the main stage and upper stage were loaded into the purpose-built hybrid sailing ship Canopée at the harbours of Bremen, Germany, and Le Havre, France.

Canopée left the port of Le Havre carrying the last elements that will form the first Ariane 6 rocket to soar into space. Canopée is scheduled to arrive at the port of Pariacabo in Kourou, French Guiana, by the end of February. From there, the two stages will be transported by truck the last few kilometres to Europe’s Spaceport.

Stages to launch

The main stage was constructed in Les Mureaux, France, at ArianeGroup’s assembly hall. On launch day later this year, the main stage for Ariane 6 will fire its Vulcain 2.1 engine and provide steering for eight minutes on the rocket’s ascent into space.

The upper stage, also designed and built by ArianeGroup, was assembled in Bremen. The fuel tanks, Vinci engine and unique Auxiliary Power Unit provide fuel pressure, electricity and propulsion to fire multiple times on each Ariane 6 flight.

The two stages that are now en route to French Guiana form Ariane 6’s central core. They will be connected horizontally at Europe’s Spaceport before being transported a few kilometres to the launch area and lifted upright.

Once upright, two boosters will be added for Ariane 6’s first flight; they are already in French Guiana. Lastly, the upper composite fairing – a nosecone that splits vertically in two – and the payloads will be attached on the launch pad.

Making way for launch

Meanwhile teams ESA, ArianeGroup and France’s space agency CNES have started removing the Ariane 6 test model that currently stands on the launch pad. The same procedure as described above will be followed but in reverse order. The dummy payloads inside the fairing of the test model will return to the Encapsulation Hall that is part of the Bâtiment d'Assemblage Final. Then the test model will be further disassembled by removing the boosters and returning the central core to the Launcher Assembly Building.

Ariane 6 is an all-new design, created to succeed Ariane 5 as Europe's heavy-lift launch system. With Ariane 6's upper stage restart capability, Europe's launch capability will be tailored to the needs of multiple payload missions, for example to orbit satellite constellations. This autonomous capability to reach Earth orbit and deep space supports Europe's navigation, Earth observation, scientific and security programmes. Ongoing development of Europe's space transportation capabilities is made possible by the sustained dedication of thousands of talented people working in ESA's 22 Member States.

Quelle: ESA

----

Update: 23.02.2024

.

Ariane 6 ready for unloading

In time for its summer launch this year, Ariane 6 has arrived at the port of Pariacabo in Kourou, French Guiana – home of Europe’s Spaceport – and is ready to be assembled.

All the elements that make up the rocket are manufactured in mainland Europe and then transported by this novel ship, Canopée (canopy in French). It is the first custom-built transporter to use sails, reducing emissions and saving on fuel by up to 30%, and on this trip, it has travelled for 10 days covering over 7000 km.

The hybrid-propulsion vessel is 121 m long and has 37 m tall sails. Canopée rotates continuously between stop-offs to load each Ariane 6 stage and other parts and ship them across the Atlantic Ocean to Europe’s spaceport.

On this trip, Canopée brings the central core for Ariane 6’s first flight. Having collected the upper stage from Bremen, Germany, Canopée moved on to Le Havre, France, to load the main stage of Ariane 6.

The next-generation cargo ship has been designed for ArianeGroup to meet the complex requirements of Ariane 6 transport – the stages and engines of Ariane 6 are high-tech equipment that require delicate care during transport.

Canopée’s structure is tailored to carry large, fragile loads as well as navigate the shallow Kourou river to Pariacabo harbour. From here the various Ariane 6 components are offloaded and transported by road to the new Ariane 6 launch vehicle assembly building just a few kilometres away.

Here, the launcher stages are unpacked and installed on the assembly line for integration, and finally, liftoff.

Quelle: ESA

----

Update: 11.03.2024

.

The stages for the inaugural Ariane 6 flight currently being assembled

he main stage and the upper stage for the inaugural Ariane 6 flight are currently in the central core final assembly line in the Launcher Assembly Building (BAL) at the ELA4 launch complex. The central core is made up of the main stage and the upper stage, assembled together with an inter-stage interface structure. Once assembled, the central core will then be transferred from the BAL to the launch pad.

On the launch pad, the central core will be raised to the vertical position and placed on the launch table. The two boosters will then be added, one on each side, to form an Ariane 62. Finally, the upper composite consisting of the fairing and the payloads will then be added to the launcher on the launch pad.

The main stage and the upper stage arrived in French Guiana on board the transport ship Canopée on February 21, traveling from ArianeGroup’s sites of Les Mureaux (France) and Bremen (Germany).

The Ariane 6 program is managed and funded by the European Space Agency (ESA). As industrial lead contractor and design authority for the launcher, ArianeGroup is responsible for its development and production with its industrial partners, as well as for its marketing through its Arianespace subsidiary. The French Space Agency, CNES, and its contractual partners are responsible for the construction of the Ariane 6-dedicated launch pad in Kourou, French Guiana. CNES in partnership with ArianeGroup also conducts the combined tests under the responsibility of ESA.

Quelle: arianeGroup

----

Update: 15.03.2024

.

Flying first on Ariane 6

In-depth

“Ariane 6 is designed to be versatile, offering space actors bespoke launch options all while keeping costs down,” says Michel Bonnet, head of Ariane 6 missions and system engineering and ESA’s lead for the Ariane 6 inaugural flight. “The varied missions launching on the first flight, from nine countries and dozens of organisations, are a perfect demonstration of the team spirit behind this rocket and the design ethos that underpins it.”

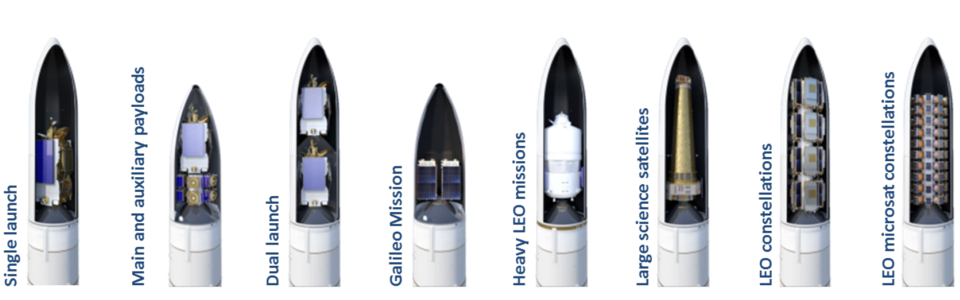

Ariane 6 possible missions and configurations

From established players like NASA to students designing their first ever satellite, these missions will measure gamma rays, track wildlife, test self-healing solar cells, confirm the theory of black body radiation and more. There's a smart-farming satellite, a radio beacon demonstrator, experiments that will remain attached to the rocket's payload ‘adaptor’ and even capsules destined to reenter Earth’s atmosphere to test new materials – Ariane 6’s first flight will be packed with technology as its first payloads are sent on their way into space.

This plethora of missions is being supplied by three types of organisations: commercial companies, space agencies and universities. Together they have been building hardware to test and prove their technology works in space; satellites to measure weather on Earth or in the Solar System; study the Sun and perform other science experiments.

Ready, set, deploy

Access the video

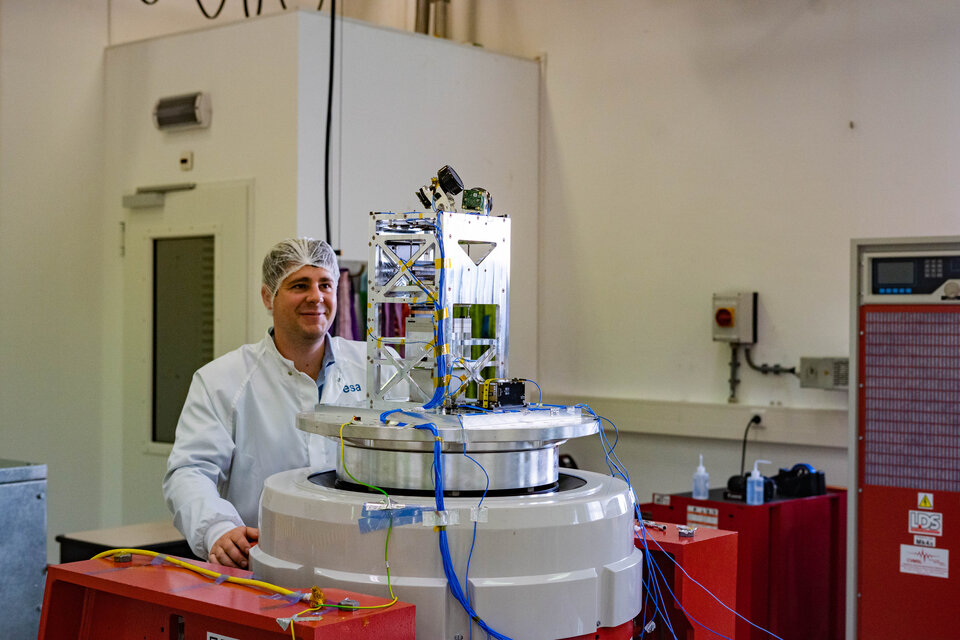

Four deployers, including the multi-CubeSat deployers RAMI and EXOpod, will release satellites away from the Ariane 6 upper stage.

The two reentry capsules and nine satellites that are set to fly free are placed at the top of the rocket in order of their release, perfectly timed to be set on their way after leaving their Ariane 6 nest, 600 km above Earth.

Cubesat deployers are like mini launchers in their own right, orchestrating a series of spring-loaded ejections to shoot one or multiple miniature satellites from the Ariane launcher at the right time, speed and in the right direction to set them on their way. As the CubeSats don’t have their own propulsion, they will stay in the same orbit Ariane 6 releases them into.

Many missions

Not all the missions will fly free. One mission, YPSat, will stay attached to the upper stage of the Ariane 6 to record the whole mission from launch to end. Four other experiments will remain fixed, performing their work for the duration of the rocket’s flight and returning altogether in unison, like skydivers holding tight for their Earth descent.

“The first flight of a new rocket is always an astounding moment as there are hundreds of thousands of details that have to work in perfect harmony – for the first time together in full,” says Loïc Bourillet, head of ESA’s Collective Launch Service Procurement.

“Rather than only launching an inert dummy payload as a stand in for larger satellites, we have a large platform that also offers a unique opportunity to accommodate smaller, data gathering payloads. I am incredibly pleased with the scale of space hardware that has been designed and built. It’s a testament to the inventive minds of our generation.”

All eyes on Ariane 6

ESA’s young professional satellite, YPsat, will take pictures and video of the Ariane 6 rocket itself once it flies free. Tatjana Mandil, a communications officer for YPsat during her work as a trainee engineer on lunar Gateway modules, said “A launcher’s first flight is always much anticipated and attracts lots of attention. It is going to be wild to know our team’s satellite is at the top of ESA’s new rocket, and we hope to add to the spectacle when we can share the video of the satellites releasing into Earth orbit.”

Each passenger will be highlighted in an individual article over the next few months.

| Name | Organisation | Mission type |

| SpaceCase SC-X01 | ArianeGroup | Reentry capsule |

| Bikini Capsule | The Exploration Company | Reentry capsule |

| PariSat | Garef Aerospatial | Experiment |

| Peregrinus | Sint-Pieterscollege | Experiment |

| LIFI | OLEDCOMM | Experiment |

| SIDLOC | Libre Space | Experiment |

| YPSat/Eye2Sky | ESA | Experiment |

| OOV-Cube | RapidCube | Cubesat & deployer |

| Curium One | Planetary Transportation System | Cubesat 12U & deployer |

| RAMI | UARX Space | Deployer 12U |

| ExoPod NOVA | ExoLaunch | Deployer 16U |

| ISTSAT | ESA Education Office/University of Lisbon | Cubesat 1U |

| 3Cat4 | ESA Education Office/Universitat Politècnica de Catalunya | Cubesat 1U |

| GRBBEta | Spacemanic | Cubesat 1U |

| ROBUSTA-3 | CSUM | Cubesat 3U |

| CURIE | NASA | Cubesat 2x3U |

| REPLICATOR | RIDE!space / Orbital Matter | Cubesat 3U |

| Ride!6U | RIDE!space | Cubesat 6U |