15.12.2021

Boeing to Move Up Service Modules for Commercial Crew Flight Tests

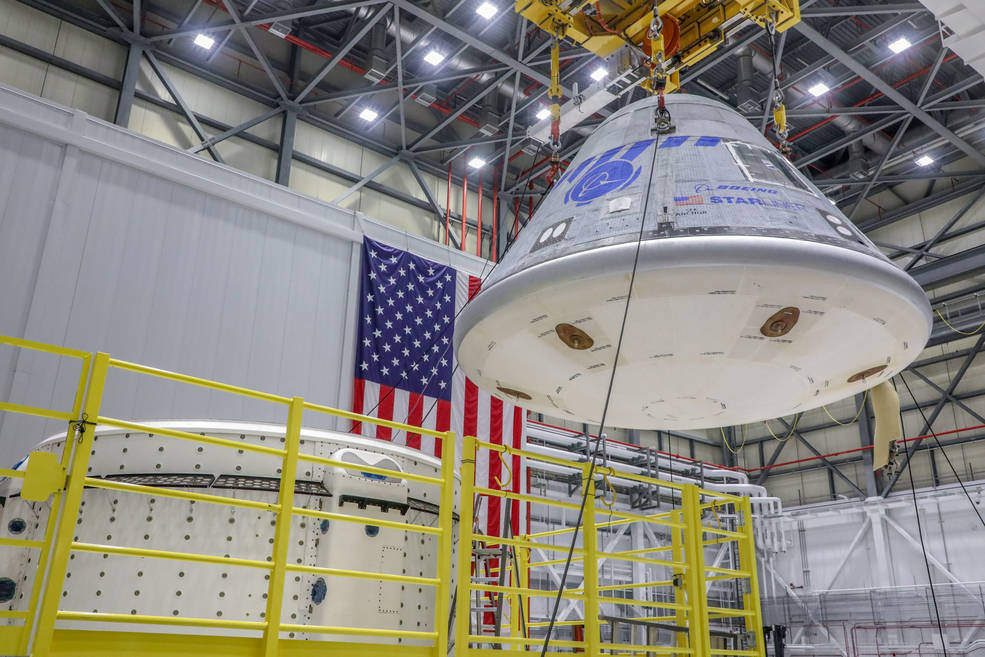

On July 29, 2021, Boeing’s CST-100 Starliner spacecraft and the United Launch Alliance Atlas V rocket rolled out of the Vertical Integration Facility to the launch pad at Space Launch Complex-41 on Cape Canaveral Space Force Station in Florida. Starliner will launch on the Atlas V for Boeing’s second uncrewed Orbital Flight Test (OFT-2) for NASA’s Commercial Crew Program. Photo credit: NASA/Kim Shiflett

Following extensive testing and analysis of oxidizer isolation valves on Boeing’s CST-100 Starliner service module propulsion system, Boeing has decided to move up service modules currently in production for its upcoming uncrewed and crewed flight tests to the International Space Station as part of NASA’s Commercial Crew Program.

The service module originally planned for its Crew Flight Test (CFT) will now be used for the Orbital Flight Test-2 (OFT-2) mission, and the service module planned for the Starliner-1 flight will be used for CFT.

“NASA has been working side-by-side with Boeing on the service module valve investigation, including leveraging the agency’s materials and propellants expertise to better characterize the potential causes of the issue,” said Steve Stich, manager, NASA’s Commercial Crew Program. “Because of the combined work, we have a much better understanding of the contributors that led to the valve issues, and ways to prevent it from happening in the future. Boeing remains diligent and driven by the data during its decision making, which is key to ensuring the Starliner system is ready when we fly our test missions in 2022.”

Ongoing investigation efforts continue to validate the most probable cause to be related to oxidizer and moisture interactions. NASA and Boeing will continue the analysis and testing of the initial service module on which the issue was identified leading up to launch of the uncrewed OFT-2 mission in August 2021.

“Our objective was to get back to flight safely and as soon as possible. With this objective in mind, we set out on parallel paths: remediating valves to preserve the option of utilizing the existing service module (SM2), while also working to accelerate the build of the next service module (SM4),” said John Vollmer, vice president and program manager, Boeing’s Commercial Crew Program. “Based on the results to date we’ve decided to fly SM4 next and continue longer term tests with SM2 hardware, on the vehicle and in offline facilities.”

Teams conducted extensive analysis on the valves in Boeing’s Commercial Crew and Cargo Processing Facility, NASA’s Marshall Space Flight Center and outside laboratories. That analysis included testing samples of the corrosion, using specialized micro CT scans and borescopes to see inside the valves, exposing parts of valves to various conditions, and removing and disassembling several valves.

“I am incredibly proud of the entire NASA and Boeing team for their creativity and technical excellence while working this investigation,” Stich said.

Testing is continuing at NASA’s White Sands Test Facility to expose the valves to conditions similar to those that the spacecraft experienced inside the factory and at the Atlas V launch pad and Vertical Integration Facility prior to the last launch attempt.

Testing has already taken place on the former CFT, now OFT-2, service module to ensure the health of the hardware. The team will also apply preventative remediation efforts to this service module to prevent similar issues from occurring. The team is now working through next steps for removing and replacing the service module.

“The members of the combined team are consummate professionals, who continue to safely and systematically troubleshoot and safe the wet propellant system,” said Vollmer. “I’m very proud of their resolve.”

NASA, Boeing, United Launch Alliance and the Eastern Range continue to assess potential launch windows for OFT-2. As part of the standard process for requesting a launch slot on ULA’s manifest in the first half of 2022, Boeing has agreed to an open window in May, pending spacecraft readiness and space station availability. Potential launch windows for CFT are under review.

Quelle: NASA

----

Update: 21.12.2021

.

Boeing Starliner test flight planned for spring 2022

WASHINGTON — NASA and Boeing are planning no earlier than May 2022 for the rescheduled second uncrewed test flight of the CST-100 Starliner spacecraft after deciding to change service modules for that mission.

Under the revised plan, the service module that had been built for the Crew Flight Test (CFT) mission, the flight of that vehicle to carry people, will instead be used for the Orbital Flight Test (OFT) 2 mission. The CFT mission will instead use the service module for the first operational mission, called Starliner-1.

That approach could allow the OFT-2 mission to launch in the spring. Boeing will work United Launch Alliance, whose Atlas 5 will launch the spacecraft, and the Eastern Range to consider a launch opportunity in May. That date will depend on both the readiness of the spacecraft and the schedule of other vehicles visiting the International Space Station.

“Our objective was to get back to flight safely and as soon as possible. With this objective in mind, we set out on parallel paths: remediating valves to preserve the option of utilizing the existing service module (SM2), while also working to accelerate the build of the next service module (SM4),” John Vollmer, vice president and program manager for Boeing’s commercial crew program, said in a Dec. 13 statement. “Based on the results to date we’ve decided to fly SM4 next and continue longer-term tests with SM2 hardware, on the vehicle and in offline facilities.”

Boeing scrubbed an August launch of the OFT-2 mission when valves in the propulsion system of service module failed to open. The investigation has focused on nitrogen tetroxide oxidizer that permeated Teflon seals in the valves and reacted with moisture on the other side. That created nitric acid that corroded the seals and caused them to remain shut.

However, the exact nature of the problem — not seen on the original OFT mission in December 2019 — and how to fix it remain unclear. “Ongoing investigation efforts continue to validate the most probable cause to be related to oxidizer and moisture interactions,” NASA said in the statement, but didn’t elaborate on topics like the source of the moisture and how to resolve the problem.

NASA and Boeing said they were making “preventative remediation efforts” to the new service module for the OFT-2 mission. Engineers also tested the module to confirm it was in good condition before moving ahead with plans to swap out the service modules.

Steve Stich, NASA commercial crew program manager, said in the statement that the agency and Boeing have been working together to investigate the problem, including tests at NASA facilities. “Because of the combined work, we have a much better understanding of the contributors that led to the valve issues, and ways to prevent it from happening in the future,” he said. “Boeing remains diligent and driven by the data during its decision making, which is key to ensuring the Starliner system is ready when we fly our test missions in 2022.”

While that comment suggested NASA and Boeing still play to fly the CFT mission before the end of 2022, that schedule will be challenging even if OFT-2 flies in May 2022. For example, more than a year elapsed between SpaceX’s two Crew Dragon test flights, the uncrewed Demo-1 mission in March 2019 and the crewed Demo-2 launch in May 2020. In the statement, NASA said only that potential launch dates for CFT are under review.

Quelle: SN

----

Update: 27.02.2022

.

Boeing Starliner chief to retire, but staying on through next flight test

Boeing's Starliner program leader will soon retire from the company but stay on as an adviser through the capsule's test flight later this year, according to a memo sent out to employees this week.

With a 35-year career under his belt, John Vollmer, vice president and manager of Boeing's Commercial Crew Program, is slated to retire from the aerospace giant in early March. He was instrumental in the development of Starliner, one of two capsules chosen by NASA to return astronauts to the International Space Station after the space shuttle program ended in 2011.

The announcement was made Thursday by Jim Chilton, Boeing's senior vice president of space, and a copy of the memo was obtained by FLORIDA TODAY.

"John Vollmer is someone who has shown us what a 35-year Boeing career looks like," Chilton said in the memo (see the full text below). "Thankfully, John has offered to stay on board as an advisor to the program through Starliner’s (next) mission. This transition period will enable shared learning and strengthens program continuity."

Starliner flew its first uncrewed test flight in December 2019, but it failed to reach the ISS due to software and hardware issues, forcing a turnaround back to Earth and safe landing in New Mexico. Boeing has opted to pay out of its own pocket for a second test flight, known as Orbital Flight Test 2 or OFT-2, which is set to fly no earlier than May.

Once operational, Starliner will join SpaceX's Crew Dragon capsule in transporting astronauts to and from the ISS. SpaceX has so far hosted four crewed launches to the station.

Vollmer kicked off his space career as a space shuttle engineer, helped develop the ISS and eventually became its chief engineer, and has since led the Starliner team at Kennedy Space Center.

Filling his position on March 4 will be Mark Nappi, the current Boeing program director for NASA's Artemis I mission slated for launch no earlier than May. Boeing also builds the core stage of the massive Space Launch System rocket, a separate vehicle from Starliner designed to take astronauts to farther destinations like the moon and Mars.

In that role, Chilton said, Nappi was responsible for "assembling the workforce, establishing operations processes, commencing production of the core stage, performing a full-flight duration hot fire test, and ensuring readiness for the upcoming wet dress rehearsal and launch of SLS on the Artemis I mission."

Before Boeing, Nappi led two contracts at KSC with United Space Alliance and Vencore. He also worked on the shuttle, ISS support, and the Ares I-X rocket that ultimately did not replace the shuttle as planned. He was on the team that made possible the shuttle program's last flight of Atlantis in July 2011.

"Mark’s extensive operations experience uniquely qualifies him for this position, especially as the program transitions from the design, development, test and evaluation phase toward operational flights," Chilton said.

Artemis I will include an uncrewed, Lockheed Martin-built Orion capsule that will fly to the moon, orbit it, then return back to Earth. Artemis II will run the same test but with astronauts, while Artemis III will eventually see two Americans set foot on the surface no earlier than 2025.

Quelle: Florida Today

----

Update: 13.03.2022

.

Boeing Starliner test flight next on ULA’s launch schedule

Boeing’s Starliner spacecraft inside the Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida. Credit: Boeing

The U.S. Space Force has postponed a multi-spacecraft mission that was booked to fly on a United Launch Alliance Atlas 5 rocket in April, moving a redo of a test flight for Boeing’s Starliner crew capsule to the front of the line on ULA’s launch schedule.

ULA announced the delay in the Space Force’s USSF 12 mission in a brief statement shared on social media. The launch company, a 50-50 joint venture between Boeing and Lockheed Martin, said the delay was ordered at the request of the Space Force’s Space Systems Command.

“We will continue to work with SSC to determine USSF 12’s next launch opportunity,” ULA said.

The Starliner test flight, delayed from last August, was tentatively scheduled to launch from Cape Canaveral on May 20 before the delay in the USSF 12 mission. The USSF 12 postponement is not expected to allow the Starliner mission to move forward significantly.

The USSF 12 mission was set to launch in the first half of April with two Space Force payloads heading for geosynchronous orbit, a location more than 22,000 miles (nearly 36,000 kilometers) over the equator.

The Space Force’s Wide Field of View, or WFOV, surveillance satellite is the primary payload on the USSF 12 mission. The WFOV satellite is a testbed for a next-generation space-based sensor designed to detect rocket launches and provide early warning of a missile attack.

Built by Millennium Space Systems, the WFOV testbed satellite will host an optical staring instrument to detect the exhaust plumes from missile launches, demonstrating the wide-area sensor for future use in the military’s operational early warning systems.

Boeing’s Starliner team at Kennedy Space Center is readying the crew-rated spacecraft for a launch opportunity in May, a mission that now becomes the next flight on ULA’s Atlas 5 schedule.

The Starliner mission is a redo of an unpiloted test flight in December 2019 cut short by software problems. The software issues prevented the spacecraft from docking with the International Space Station, and the capsule safely landed in New Mexico after an abbreviated mission.

After several hardware and software changes, Boeing readied for second attempt at the Starliner’s Orbital Flight Test mission — designated OFT-2 — last August. The spacecraft was rolled to the launch pad at Cape Canaveral atop its Atlas 5 rocket, but tests revealed stuck valves in the Starliner propulsion system.

Boeing and NASA, which manages the Starliner commercial crew contract, agreed to remove the Starliner from the Atlas 5 rocket and postpone the mission to investigate the valve problem. Engineers believe the valve components likely corroded from the interaction of nitrogen tetroxide propellant with moisture that seeped into the thrusters on the spacecraft’s service module, then permeated a Teflon seal inside the valve itself.

Technicians removed the service module from the Starliner’s crew module in January for shipment to a test facility in New Mexico, where teams are performing tests to better understand the valve problem. The OFT-2 mission will fly with a new service module, one originally assigned to the first Starliner mission with astronauts.

Boeing said the Starliner team designed a new purging system to help prevent moisture from getting into the valves during the upcoming launch campaign while the spacecraft is in the factory and at ULA’s launch site.

A Boeing spokesperson did not respond to questions from Spaceflight Now.

If successful, the OFT-2 mission will pave the way for Starliner’s Crew Flight Test, which will carry a team of three NASA astronauts to the space station. That will ultimately lead to operational crew rotation flights on the Starliner spacecraft, akin to SpaceX’s Crew Dragon missions to the space station, giving NASA two U.S. vehicles capable of ferrying astronauts to and from the orbiting research complex.

Quelle SN

----

Update: 16.04.2022

.

NASA Invites Media to Cover Boeing’s Orbital Flight Test-2 Mission

Media accreditation is open for prelaunch and launch activities for NASA’s Boeing Orbital Flight Test-2 (OFT-2) mission to the International Space Station, the second uncrewed flight test of the company’s CST-100 Starliner spacecraft for the agency’s Commercial Crew Program.

Liftoff on the United Launch Alliance Atlas V rocket with Starliner is targeted for Thursday, May 19, from Space Launch Complex-41 at Cape Canaveral Space Force Station in Florida.

NASA and Boeing will hold a joint media teleconference at 11 a.m. EDT Tuesday, May 3, to discuss the OFT-2 mission and provide an update on spacecraft readiness. The teleconference will include the following participants:

- Kathryn Lueders, associate administrator, NASA’s Space Operations Mission Directorate

- Steve Stich, manager, Commercial Crew Program, NASA’s Johnson Space Center in Houston

- Dr. Michelle Parker, vice president and deputy general manager, Space and Launch, Boeing

- Mark Nappi, vice president and program manager, CST-100 Starliner, Boeing

Audio of the teleconference will stream live on the agency’s website.

The uncrewed mission will test the end-to-end capabilities of the Starliner spacecraft and Atlas V rocket from launch to docking and return to Earth at one of five designated landing zones in the western United States. Following a successful completion of the OFT-2 mission, NASA and Boeing will determine a launch window for NASA’s Boeing Crew Flight Test (CFT), Starliner’s first flight with astronauts aboard.

OFT-2 and CFT will provide valuable data toward NASA certifying Boeing’s crew transportation system for regular flights with astronauts to and from the space station.

Media accreditation and mission overview teleconference participation deadlines for the OFT-2 launch are as follows (all times Eastern):

- Media interested in participating in the OFT-2 mission overview news teleconference must RSVP by 10 a.m. Tuesday, May 3.

- U.S. media interested in covering the OFT-2 launch must apply for credentials by 5 p.m. Sunday, April 24.

- All international media, including U.S.-based international media without U.S. citizenship, interested in covering the OFT-2 launch must apply by 5 p.m. Sunday, April 17.

All accreditation requests should be submitted online at:

For questions about media accreditation, email: ksc-media-accreditat@mail.nasa.gov. For other questions, contact the newsroom at NASA’s Kennedy Space Center in Florida at: 321-867-2468.

Special logistical requests, such as space for satellite trucks, tents, or electrical connections, should be sent: ksc-media-accreditat@mail.nasa.gov by 5 p.m. Friday, May 6.

Para obtener información sobre cobertura en español en el Centro Espacial Kennedy o si desea solicitar entrevistas en español, comuníquese con Antonia Jaramillo: 321-501-8425.

NASA’s Commercial Crew Program is working with the American aerospace industry through a public-private partnership to launch astronauts on American rockets and spacecraft from American soil. The goal of the program is to provide safe, reliable, and cost-effective transportation to and from the International Space Station, which will allow for additional research time and will increase the opportunity for discovery aboard humanity’s testbed for exploration. The space station remains the springboard to NASA's next great leap in space exploration, including future missions to the Moon and eventually to Mars.

Quelle: NASA

----

Update: 23.04.2022

.

ULA begins stacking Atlas 5 rocket for Boeing’s Starliner test flight

An Atlas 5 first stage, with its Russian-made RD-180 engine, is prepared for stacking outside ULA’s Vertical Integration Facility on Wednesday morning. Credit: United Launch Alliance

Final assembly of a United Launch Alliance Atlas 5 rocket began Wednesday with the hoisting of a first stage booster onto a mobile launch platform at Cape Canaveral, kicking off a campaign to prepare for liftoff May 19 on a delayed unpiloted test flight of Boeing’s Starliner crew capsule.

ULA’s ground team raised the Atlas first stage off its trailer transporter, and a crane lifted the rocket into the Vertical Integration Facility Wednesday morning. The 107-foot-tall (33-meter) rocket stage was then lowered onto the Atlas 5’s mobile launch platform inside the integration building just south of ULA’s launch pad at Space Launch Complex 41.

The milestone event Wednesday, known as Launch Vehicle On Stand, will be followed in the coming days by the addition of two strap-on AJ-60A solid rocket boosters made by Aerojet Rocketdyne. Then a dual-engine Centaur upper stage will be raised on top of the Atlas first stage to complete the initial build-up of the launcher.

In early May, Boeing and ULA will move the Starliner spacecraft from its hangar at the Kennedy Space Center to the VIF for stacking atop the Atlas 5.

The launch preparations will culminate in rollout of the Atlas 5 rocket and Starliner spacecraft to pad 41 on May 18. Liftoff to begin Boeing’s Orbital Flight Test 2 mission to the International Space Station is scheduled for 6:54 p.m. EDT (2254 GMT).

The mission is scheduled to last approximately one week, with docking at the space station scheduled the day after liftoff. The Starliner capsule will return to Earth for a parachute-assisted, airbag-cushioned landing at one of Boeing’s recovery sites in the Western United States.

The Starliner demo, known as OFT-2, mission is a redo of an unpiloted test flight in December 2019 cut short by software problems. The software issues prevented the spacecraft from docking with the International Space Station, and the capsule safely landed in New Mexico after an abbreviated mission.

After several hardware and software changes, Boeing readied for second attempt at the Starliner’s Orbital Flight Test mission — designated OFT-2 — last August. The spacecraft was rolled to the launch pad at Cape Canaveral atop its Atlas 5 rocket, but tests revealed stuck valves in the Starliner propulsion system.

Boeing and NASA, which manages the Starliner commercial crew contract, agreed to remove the Starliner from the Atlas 5 rocket and postpone the mission to investigate the valve problem. Engineers believe the valve components likely corroded from the interaction of nitrogen tetroxide propellant with moisture that seeped into the thrusters on the spacecraft’s service module, then permeated a Teflon seal inside the valve itself.

Technicians removed the service module from the Starliner’s crew module in January for shipment to a test facility in New Mexico, where teams are performing tests to better understand the valve problem. The OFT-2 mission will fly with a new service module, one originally assigned to the first Starliner mission with astronauts.

Teams inside Boeing’s Starliner hangar mated the crew module with the new service module March 12. Filling of the service module with propellant is expected to occur this month, before the spacecraft rolls over to ULA’s rocket integration building for stacking atop the Atlas 5.

Boeing said the Starliner team designed a new purging system to help prevent moisture from getting into the valves during the upcoming launch campaign while the spacecraft is in the factory and at ULA’s launch site.

If successful, the OFT-2 mission will pave the way for Starliner’s Crew Flight Test, which will carry a team of three NASA astronauts to the space station. That will ultimately lead to operational crew rotation flights on the Starliner spacecraft, akin to SpaceX’s Crew Dragon missions to the space station, giving NASA two U.S. vehicles capable of ferrying astronauts to and from the orbiting research complex.

Following the grounding of the OFT-2 last year, ULA removed the Atlas 5 rocket’s dual-engine Centaur stage and solid rocket boosters, but kept the launcher’s core stage in position on its mobile platform. Ground teams added a different version of the Centaur upper stage for the launch of NASA’s Lucy asteroid explorer last October.

The solid rocket boosters and dual-engine Centaur upper stage were kept in storage for the last eight months until Boeing engineers could ready the Starliner spacecraft for another launch campaign.

A new Atlas first stage was delivered to Cape Canaveral last week from ULA’s factory in Decatur, Alabama, on NASA’s Pegasus rocket barge, a vessel originally built to ferry space shuttle external tanks between their manufacturing site in New Orleans and the Kennedy Space Center.

Since the retirement of the shuttle, the Pegasus barge has been modified to carry the core stage of NASA’s Space Launch System moon rocket. ULA’s rocket ferry, named the R/S RocketShip, is currently in a routine dry dock period and river locks on the typical route from Decatur to Cape Canaveral are closed for maintenance, ULA said.

On previous occasions when the RocketShip vessel was unavailable, ULA has used Ukrainian-built Antonov An-124 cargo planes to fly Atlas booster stages from Alabama to the launch site. Those aircraft are owned and operated by Russia’s Volga-Dnepr Airlines. Russian aircraft are banned from U.S. airspace in the aftermath of Russia’s military invasion of Ukraine.

Without the Antonov cargo planes, ULA turned to NASA to use its rocket barge to deliver the Atlas first stage to Cape Canaveral and keep the Starliner’s OFT-2 mission on track for launch in May.

Quelle: SN

----

Update: 30.04.2022

.