27.01.2020

SLS Core Stage in Stennis B-2 Stand to start Green Run campaign

The Green Run test campaign for the first NASA Space Launch System (SLS) Core Stage is underway with the rocket now installed in the B-2 position at the B Test Stand at the Stennis Space Center (SSC) in Mississippi. After waiting several days for acceptable weather conditions, the stage was finally lifted into the stand on January 22 following its arrival at Stennis on-board the Pegasus barge on January 12. The barge trip from Michoud Assembly Facility (MAF) was also postponed by weather for a couple of days.

Along with the performance of the stage as it is activated in the stand, the weather will continue to play a role in how long it takes to conduct all the tests and fix up the stage to ship to the Kennedy Space Center for Artemis 1 launch preparations. The test team at Stennis will first perform a modal test on the stage before fully connecting it to the facilities in the test stand.

Stage activation and checkouts will lead up to the stage’s first propellant loading, followed by an eight-minute long, flight-duration firing of the stage and its four engines.

Vertical lift waits for favorable weather

Two cranes began the overnight installation of Core Stage-1 into B-2 position of the test stand on January 21. After a “lift spider” was attached to the weather cover on top of the forward skirt, the stand’s derrick crane was attached to the spider and a commercial crane was rigged to pick up the back of the stage at two points on the outside of the engine section section barrel.

The stage was disconnected from the NASA Multi-Purpose Transportation System (MPTS) interface structures and the cranes lifted the stage off the carrier horizontally. Once it was high enough the cranes rotated the stage, breaking it over from horizontal to vertical, with the derrick crane on the stand raising the top of the rocket up and the trailing crane lowering the bottom.

Once the stage was vertical the trailing commercial crane was disconnected and the stand’s crane finished the installation, lifting the stage up, pivoting it into the B-2 position of the stand, and lowering it down over the holddown posts in the stand for install.

Credit: NASA/SSC.

(Photo Caption: Two cranes breakover Core Stage-1 above the tarmac of the B Test Stand at Stennis Space Center on the night of January 21. In the foreground, a commercial crane is attached to connection points on the engine section Solid Rocket Booster (SRB) structural ring. In the background, the stand’s derrick crane raises a lift spider attached to the front of the forward skirt. Technicians hold rope lines attached to other points around the SRB ring to minimize any unwanted swinging motions of the stage while it is suspended in the air.)

There are wind limits to safely perform the lift, breakover, and install and the plan was to do most of the operation during overnight hours when wind speeds are typically lower. As with the barge transport from Michoud, winter weather prevented teams from getting the stage up and into the stand for several days.

The stage was rotated from horizontal to vertical at least twice before, but the stage has to be lifted over 150 feet above ground level while hanging from the stand’s derrick crane. Rope lines tied to points on the bottom of the stage are used by workers to manually help dampen and arrest unwanted motions, but the wind is still an issue for the over 200-foot long rocket.

Core Stage-1, which will eventually help launch the uncrewed Artemis 1 test flight to orbit the Moon, arrived at Stennis for the Stage Green Run campaign onboard the agency’s Pegasus barge on January 12. Pushed and pulled by tug boats, Pegasus was tied up to the dock for the B Test Stand in the late afternoon after departing MAF in New Orleans early that morning.

The first flight article and first program working article rolled out of the factory at MAF on January 8. The stage and its transportation carrier were secured on Pegasus a few hours after the rollout, but the trip on the water from MAF to Stennis had to wait a few days for acceptable weather conditions.

Credit: NASA/SSC.

(Photo Caption: The derrick crane pivots the vertical Core Stage into the B-2 position of the test stand after daybreak the next morning of January 22. The trailing crane was disconnected from the bottom of the stage after breakover from horizontal to vertical, allowing the stand’s crane to lift it up and over to the B-2 position and then lower it into place over the hold downs in the stand.)

Once the barge was tied up to the dock preparations began to lift the stage into the stand, following the same outline of steps performed several months ago with the Core Stage Pathfinder when it was at Stennis. Within a few hours of arrival, the self-propelled modular transporters (SPMT) that rode with the stage and the rest of the NASA Multi-Purpose Transportation System (MPTS) on the barge from Michoud picked up the stage and its carrier, rolled them off Pegasus, and set them down onto the tarmac at the stand.

By the time Stennis employees were invited to view the stage from the perimeter area around the test stand on January 14, the team had installed the lift spider and the trailing crane rigging was connected to the aft end of the stage. The stage was rotated from horizontal to vertical at least once by the end of the first week on site and again at the end of the holiday weekend; without good enough conditions for long enough to continue the lift and install, the stage was rotated back to horizontal again before the weather finally cooperated a few days later to safely lift the stage up into the stand.

The stage will be outside in the elements at Stennis for the remainder of the test campaign until it is removed from the stand and rolled back onto Pegasus, so technicians will have to suspend work and take shelter indoors when weather conditions such as lightning or high winds make it unsafe to continue. The amount of time the weather holds up work is one of the uncertainties in forecasting how long the campaign at Stennis will take to complete.

Modal test up first

The first activity with the stage in the stand is a modal test to measure the standalone structural frequency response of the Core Stage. “As soon as we get it in the stand we’ll take about two or three weeks where we’re going to do something called a modal, which is essentially just a response test to see how the vehicle reacts, again matching up those results with the models that we’ve created to make sure that it’s reacting like we expected it to,” Mark Nappi, Boeing Green Run Test Manager, said in a December media session at the stand.

Ground test instrumentation and wiring bundles for the modal test were arrayed on the surface of the vehicle’s TPS during production at MAF; those are now being connected to the data acquisition system for the test stand. After the wiring is connected, the instrumentation will be verified to be in working condition.

With the derrick crane connected again to the lift spider the stage will be partially lifted a few inches off the holddowns in the stand so it is hanging on the crane to perform the test. “We lift it three times, so we take it, lift it up, do the modal test, put it back in the stand,” Nappi noted. “Do some data analysis, come back again pick it up, do modal, put it back in the stand. Same thing, three times.”

Credit: NASA/SSC.

(Photo Caption: As seen from the platforms on an upper level of the B-2 position of the stand, the stand crane holds a lift spider attached to the top of the Core Stage. The crane will again pick up the lift spider and the stage a few more times for the upcoming runs of the modal test.)

“Once we’re done with modal then we’ll bolt the vehicle down in the stand and we’ll start getting access,” Nappi explained. “We’ve got to get access into the engine section, we have to get access into the intertank, we have to get access into the forward skirt so that we can start configuring the vehicle for test.” In parallel with re-establishing internal access, now vertically at Stennis versus horizontally at MAF, once the work platforms around the stage are deployed technicians will remove the external modal test instrumentation.

Recent notes provided in L2 indicate the early milestones in the stand following the initial installation and modal test include establishing engine section access, connecting the Core Stage Controller avionics and software to the stage’s computer system, mating the ground side umbilicals to the vehicle, completing connection of the liquid hydrogen (LH2) lines in the engine compartment, and avionics power-up testing.

In addition to deploying the stand’s outside work platforms around the stage exterior, re-establishing access to the vehicle in the vertical will include opening access doors, removal of engine fairings around the boattail, and re-assembly of internal access platform kits inside the dry elements of the stage, the forward skirt, intertank, and engine section/boattail. The kits are similar, but not identical to the ones used at MAF most of last year during horizontal final assembly.

Credit: NASA/SSC.

(Photo Caption: Looking up at the -Z side of the Core Stage during installation into the stand on January 22. Several ground support equipment covers are attached during shipping and handling work; after the modal test, the two red access doors will be opened to begin installing work platforms inside the forward skirt above and the intertank below. The black panels cover the forward skirt umbilical above, and the intertank umbilical below. Some other protuberances seen here will also be updated prior to launch; the series of red plates on the systems tunnel are temporary covers. The black liquid oxygen (LOX) feedline fairing to the right of the systems tunnel will eventually be covered with thermal protection system (TPS) cork and painted white.)

“They are different kits,” Amanda Gertjejansen, Core Stage-1 Operations Manager for Boeing, said. “I say that, it’s a different kit for the intertank and for the boattail but you are still using the kit that we used when the engine section was vertical [during standalone integration] so you’re using a piece of that. You’re using some of that kit.”

Once the platforms are set up inside the engine section and boattail, the final connections, securing, and TPS closeouts of the LH2 Main Propulsion System (MPS) feedlines and fill/drain line can be completed. Those are the assembly/production tasks that were carried to Stennis because they were originally planned to be done vertically; when final assembly of the stage was changed to finish it horizontally, the work set was the only leftover without a horizontal alternative.

Subsequently, plans and new tooling were designed to complete the connections horizontally for final assembly of future Core Stages.

After the LH2 lines are structurally and electrically connected, mechanically checked out, and final spray-on foam insulation (SOFI) closeout work completed, the power-up testing begins activation of the vehicle to verify that it is ready for the Wet Dress Rehearsal (WDR) propellant loading test and hot-fire test that are the centerpiece of the campaign. The cryogenic tankings and stage test-firing will be firsts for the SLS Program.

“We’ll do what we call power-up testing or confidence testing,” Nappi explained. “This is the first time that this vehicle has been in this stand and has seen the software that we’ve created to run these tests, so we want to take a really slow and methodical set of steps to make sure that that all works together properly so that when we do go do the wet dress and the hot-fire everything is working like it’s supposed to.”

Credit: NASA/SSC.

(Photo Caption: As seen from ground level around the B Test Stand on January 22, the stand’s crane has lifted Core Stage-1 up over the booster support frame of the B-2 position. The crane then finished moving the stage over the B-2 centerline so it could be lowered to install in the hold downs.)

“The tests are validating that all of our systems are working, that our avionics systems are working, our hydraulic systems are working, TVC (thrust vector control) systems are working, our Main Propulsion Systems are all working. We’ll have people in our control room that will be monitoring all their systems as we bring every single black box up and we actuate every valve and we’re checking to make sure that when we send the command that it works and the indications come back and they’re coming back like they’re supposed to.”

“So we’re going to take a couple of months testing everything with the software and the vehicle and the stand to make sure that it works right,” he added. “When we’re done with that we’re going to take a step back and say it’s time to load this vehicle with LH2 and LOX (liquid oxygen) and see how it reacts.”

Boeing developed the Stage Controller (short for the Core Stage Controller) package of ground software and avionics that manages the ground control side of the Stennis testing. The Stage Controller computer racks are located on the test stand and computer package provides the interface between the test control center and the vehicle’s three redundant flight computers.

“I talked about power-up testing that we’re going to do first, that’s the Phase 1 Stage Controller,” Nappi said in December. “That’s going to be ready about the mid part of January so that the current emulator can be disconnected and the vehicle can be hooked up. And then the Phase 2 set of software with some minor modifications — there’s still some work that has to be done for hot-fire — will be available at the end of March.”

Credit: NASA/SSC.

(Photo Caption: The bottom of the Core Stage is lowered into place in the B-2 position of the test stand. The umbilical carrier mechanisms in the foreground will eventually move the ground-side umbilical plates into position to be connected to the vehicle’s flight-side tail service mast plates. The cryogenic propellant for the stage’s liquid oxygen (LOX) and liquid hydrogen (LH2) tanks will enter the stage through these two umbilicals during loading operations.)

A variation of the SLS flight software will run on the stage’s flight computers for the Stennis testing campaign called Green Run Application Software (GRAS); the flight software is called Flight Computer Application Software (FCAS).

“The biggest difference between FCAS which is the load of software that will fly the vehicle and GRAS is since we’re not flying the stage instead of having the GN&C (guidance, navigation, and control) algorithms we replace those with a Green Run subsystem and mode manager,” Dan Mitchell, NASA’s Technical Lead for SLS avionics and software engineering, said in an interview last year. “Part of what that mode manager does is it executes basically a table of predetermined thrust commands to each of the engines as well as TVC gimbal commands to the engines as well.”

“The engines will go through a thrust profile that looks similar to what you would see during an ascent but the TVC gimbal profile is coordinated to to minimize the loads imparted on the stage or the test stand itself. They’re all designed to be symmetric so to speak so that your thrust vector goes straight up and you’re not imparting side loads on the stage.”

Although the stage will be running in place during the static hot-fire, the flight computers are still running through Mission and Fault Management (M&FM) algorithms to monitor the health and status of the stage and command and control systems during critical WDR and hot-fire operations from propellant loading through the terminal countdown sequence. The computers will assume full control of the test at the beginning of the Autonomous Launch Sequence (ALS) less than thirty seconds before engine ignition; after the engines shut down, they will perform a few critical tasks like closing the LH2 and LOX prevalves before handing control back to the Stage Controller to begin comprehensive vehicle and ground system safing.

Quelle: NS

----

Update: 4.02.2020

.

Upper Stage RL10s arrive at Stennis for upcoming SLS launches

The Stennis Space Center is currently the focal point of the milestones toward the debut launch of the Space Launch System (SLS), with the Artemis-1 Core Stage currently undergoing Green Run testing on the B-2 Test Stand and the arrival of the first set of RL10 engines that will power the rocket’s Upper Stage from Artemis-2, onwards.

Four of the engines were recently delivered, according to contractor Aerojet Rocketdyne in an update on February 3. They are set to power the Interim Cryogenic Propulsion Stage (ICPS) upper stage of the Block 1 SLS, which is currently expected to be involved with the first three Artemis missions.

The RL10 – which is used in various forms with Atlas’ Centaur Upper Stage (RL10A-3) and Delta IV’s Upper Stage (RL10B-2)- has a deep history that ranges back to the Saturn I’s S-IV Stage.

It was first tested on the ground in 1959 and debuted on a launch in 1962 in the dual engine RL10A-3 configuration.

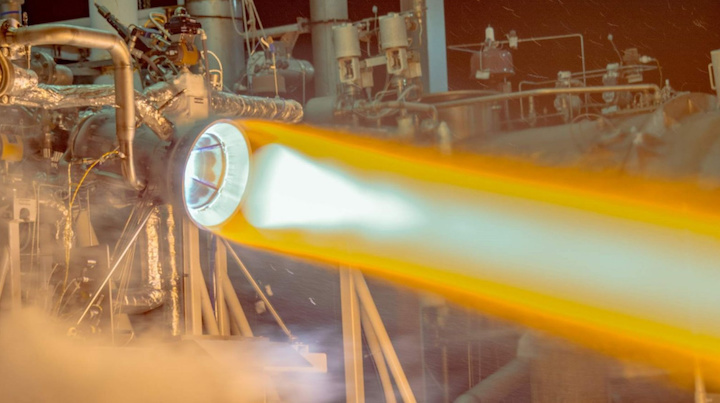

The RL-10 during a test firing – credit Aerojet Rocketdyne

“Nearly 500 Aerojet Rocketdyne RL10 engines have powered launches into space,” said Eileen Drake, Aerojet Rocketdyne CEO and president. “Aerojet Rocketdyne continues to upgrade and improve this highly-reliable, flight-proven engine.

“The RL10’s we just delivered to NASA will power the SLS upper stage on missions that safely launch our astronauts to explore deep space destinations.”

Although the ICPS was always destined to be replaced early into SLS’s lifetime, the RL10s will continue to play a role in groups of four on the SLS Block 1B’s Exploration Upper Stage (EUS).

EUS is a liquid hydrogen, liquid oxygen stage using four Aerojet Rocketdyne RL-10C3 engines.

With design changes and funding alternations to the EUS, the manifest for SLS pushed the first flight of the new Upper Stage from the second SLS launch to the fourth, behind the first Orion crew mission and launch of the Europa Clipper planetary probe.

However, this has allowed Aerojet Rocketdyne to work through engine qualification testing for EUS and all other engineering activities, including providing NASA with the information necessary for the agency to human rate the RL10 engines. Qualification of the engines for ICPS will be completed this year.

Aerojet Rocketdyne is under contract to deliver 10 RL10 engines to NASA to support the Artemis program. One RL10 has already been allocated and installed into the ICPS that will be used on the Artemis-1 mission.

One of the four engines that were recently delivered will be used to support the Artemis II mission that will use the ICPS upper stage, while the other three are slated to support future Artemis missions aboard the EUS.

The delivery of the remaining six engines will be completed by 2021.

The Upper Stage’s switch from the ICPS to the EUS will boost the initial capability of a single RL10 engine-driven stage from nearly 25,000 pounds of thrust to the four engine-driven EUS with more than 97,000 pounds of thrust.

(Photo Caption: A recently released NASA infographic provides a couple of the updated measurables for the redesigned EUS. After resizing the stage’s propellant tanks and other elements, the stage is less than a foot shorter and approximately a ton lighter when dry.)

This, in turn, increases the amount of payload that can be carried to lunar orbit; up to 40 metric tons compared to the 26 metric ton capability provided by the SLS Block 1 configuration. It also provides the option for ‘co-manifested’ payloads such as large components for NASA’s Gateway orbiting lunar outpost, landers, or surface systems.

“The EUS is really a game changer for SLS and NASA’s lunar exploration program in terms of payload mass,” said Steve Wofford, Space Launch System Program Liquid Engines manager at NASA’s Marshall Space Flight Center. “These RL10 deliveries are a key stepping stone toward that future success.”

Aerojet Rocketdyne is also involved with the four RS-25 engines that are currently waiting to fire up with the Artemis-1 SLS Core Stage, following its installation into the B-2 Test Stand at Stennis.

Months of testing is being conducted ahead of the full duration static fire test later this year, although the “Green Run” milestones are already being ticked off.

This included the recent confirmation that Modal Testing was completed with the Core Stage, which is used to measure the standalone structural frequency response of the Core Stage.

The launch of the Artemis-1 mission is currently attempting to keep to a schedule that will see it launch in Spring, 2021. Although it is becoming increasingly likely this launch date will settle for sometime in the Summer of that year.

Quelle: NS

----

Update: 6.02.2020

.

SHIIVER: Changing the way NASA Keeps it Cool

When deep space exploration missions launch, like NASA’s future Artemis missions to the Moon, they carry liquids with them for fuel and life support systems. These liquids are stored at cryogenic temperatures, which range from -243 to -423 degrees F, and to be usable, they need to remain cold and in a liquid state. But as the extreme environment of space warms a spacecraft, the fuels begin to evaporate or “boiloff.”

“As energy from the Sun, Earth, and even the Moon enters the cryogenic propellant tanks, the liquid has to absorb that energy, which causes it to boiloff,” explains Wesley Johnson, cryogenic fluid management technical lead at NASA’s Glenn Research Center in Cleveland. “Any propellant that evaporates can’t be used by the rocket and decreases the efficiency of the rocket.”

To combat boiloff, NASA’s eCryo project team is evaluating a series of technologies aimed at reducing the boiloff losses for human exploration missions. To test some of these new technologies at a relevant scale, the team built a large cryogenic propellant tank, which is more than 13 feet in diameter, called SHIIVER, or Structural Heat Intercept, Insulation and Vibration Evaluation Rig.

SHIIVER has reflective multilayer insulation as well as vapor cooling channels that minimize the heat going into the storage tank. It also uses a Radio Frequency Mass Gauge, a specialized tool designed at Glenn to accurately measure fluid levels in space. The gauge was recently demonstrated on the International Space Station.

“SHIIVER is the largest research tank NASA has ever built to test cryogenic technologies, and demonstrating the scalability is a critical aspect of infusion to in-space cryogenic propellant applications,” said Hans Hansen, eCryo project manager at Glenn.

In fall 2019, NASA engineers ran thermal vacuum tests on SHIIVER inside the In-Space Propulsion facility (ISP) located at NASA’s Plum Brook Station to assess the benefits of vapor-cooling and multilayer insulation performance for in-space conditions.

“The first vacuum test showed promising results, demonstrating total heat reduction of more than 55% compared to current system designs,” said Hansen. “The boiloff reduction varied based on the amount of fluid in the tank, but overall, the results have been positive and we’re seeing a significant reduction in boiloff.”

The SHIIVER team then used the world’s most powerful acoustic test chamber at the Space Environments Complex to simulate a dynamic launch environment, stressing the tank and thermal management features to make sure they are capable of surviving launch.

The final vacuum test, which assessed how its thermal management systems stood up to acoustic testing, was completed in January. The team is now looking for possible opportunities to demonstrate key cryogenic fluid management technologies in space.

SHIIVER is just one way NASA is improving upon state-of-the-art cryogenic propellant storage technologies, making them more energy, mass and cost-efficient. Once proven, these technologies could be used for future Artemis missions, including the large fuel tanks in the Space Launch System’s upper stage, nuclear thermal propulsion systems, future Mars transfer vehicles and cryogenic fuel depots.

Top Image: The SHIIVER tank sits inside the In-Space Propulsion Facility’s vacuum chamber at NASA’s Plum Brook Station. The tank was subjected to the extreme temperatures of space to ensure the new technologies on SHIIVER kept the propellants inside cold and in a liquid state.

Quelle: NASA

----

Update: 12.02.2020

.

Boeing works towards SLS Core Stage Green Run checkouts after completing first test

Technicians for NASA Space Launch System (SLS) Core Stage prime contractor Boeing completed the first of many tests on the program’s first working article in the test stand at the Stennis Space Center (SSC) in Mississippi and are now getting it ready for its crucial pre-launch test-firing later this year. Core Stage-1, which serves as a test article for the Green Run development campaign at Stennis, is also the flight article for the program’s first launch forecast for next year.

The Green Run campaign at Stennis is the final, major pre-launch development test of the newest piece of the space agency’s launch vehicle and the first test performed collected data on the resonant frequencies of the assembled rocket. Teams at Stennis continue to work around the clock, now establishing work platforms in and around the stage in the B-2 position at the B Test Stand to provide access to internal and external equipment.