Two of the next-generation Giant Magellan Telescope's (GMT) seven huge primary mirrors are now done.

Technicians at the University of Arizona's Richard F. Caris Mirror Lab have finished polishing the front surface of a second 27.6-foot-wide (8.4 meters) GMT mirror, a precise and exacting process that took 10 months.

The completed mirror was transported from the lab to a temporary storage facility at the Tucson Airport, joining mirror segment No. 1, Giant Magellan Telescope (GMT) officials announced today (July 31).

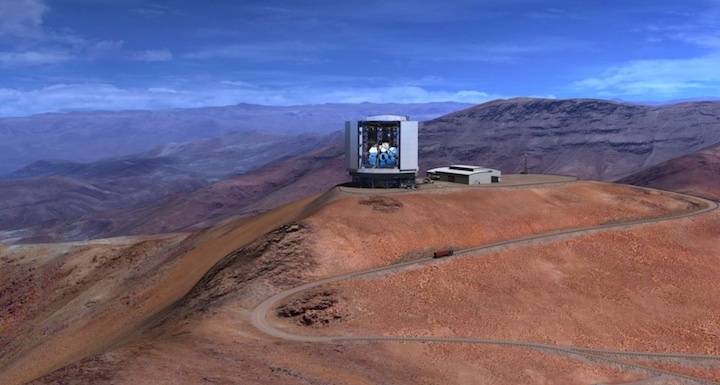

The GMT is taking shape on a mountaintop in the Chilean Andes. The telescope will feature seven primary mirrors, which together will create a light-collecting surface 80 feet (24.5 m) wide. The powerful scope will allow astronomers to investigate some of the cosmos' deepest mysteries — the nature of dark matter and dark energy, for example, and whether Earth life is alone in the universe.

The seven GMT primary mirrors are a marvel of engineering. Each one takes years to make, from the initial casting in a big, rotating furnace through multiple stages of grinding and polishing. The surfaces of the completed mirrors are perfect to within 25 nanometers — about 1 millionth of an inch.

Three of the remaining five primary mirror segments have been cast and are in various stages of processing at the Richard F. Caris Mirror Lab. The remaining two are expected to be be cast in 2020 and 2021.

Making the Giant Magellan Telescope's seven primary mirror segments is a challenging and time-consuming process.

GMT will probably begin operations with just four or five of the primary mirrors installed, project representatives have said. That's expected to happen in 2026, and the scope should be at full strength by 2028.

The primary mirrors are too big to fit in a plane, so they will eventually be shipped to Chile by sea, through the Panama Canal. They'll leave via the Port of Houston, GMT representatives said.

GMT is one of three megascopes expected to come online in the mid-2020s. The Extremely Large Telescope will observe the heavens from Chile as well, whereas the Thirty Meter Telescope will be built on Hawaii's Mauna Kea volcano.

The three giant scopes should help researchers make groundbreaking discoveries for decades to come, said Robert Shelton, president of the GMTO Corp.

"These observatories are going to last 50 years," Shelton told Space.com a few months ago.

Quelle: SC

----

Giant Magellan Telescope project casts 7th and final mirror

The huge scope is scheduled to start observing the heavens in the late 2020s.

Last week, in a spinning tank beneath the University of Arizona's football stadium, an oven kicked to life.

The oven, at the University of Arizona's Richard F. Caris Mirror Lab, began to heat a 20-ton, 27.6-foot-wide (8.4 meters) pool of optical glass to 2,130 degrees Fahrenheit (1,165 degrees Celsius), in the first steps of manufacturing a telescope mirror.

The oven's present pastry is the seventh and final mirror of the Giant Magellan Telescope, itself under construction in the mountains of northern Chile. The telescope's crown jewel will be a seven-segment mirror. When all seven pieces are in place, they will work together as a single light-collecting surface 80 feet (25.4 m) across.

Each of those mirrors must be of the highest quality, and that takes time. This last mirror will take four months to cool. After that, technicians will begin grinding and polishing its surface to an astronomically precise finish — perfect to within one one-thousandth the width of a human hair. The entire process, from baking to completion, will take four years.

Afterward, the mirror segment will journey down to Chile by boat to join its six counterparts. One of those six is currently serving as a guinea pig to test a prototype of the telescope's eventual support structure.

Astronomers expect to open the Giant Magellan Telescope's supersharp eye on the universe by the end of this decade.

The furnace lid closes for casting the Giant Magellan Telescope’s primary mirror segment seven at the University of Arizona’s Richard F. Caris Mirror Lab in September 2023. (Image credit: Damien Jemison, Giant Magellan Telescope – GMTO Corporation)

"The combination of light-gathering power, efficiency, and image resolution will enable us to make new discoveries across all fields of astronomy," Rebecca Bernstein, the telescope's chief scientist, said in a statement.

"We will have a unique combination of capabilities for studying planets at high spatial and spectral resolution, both of which are key to determining if a planet has a rocky composition like our Earth, if it contains liquid water and if its atmosphere contains the right combination of molecules to indicate the presence of life," she added.

Quelle: SC

----

Update: 20.10.2023

.

A giant European telescope rises as U.S. rivals await rescue

Past the halfway point, Extremely Large Telescope prepares to receive first mirrors

In August, the Sun rose behind the Extremely Large Telescope, under construction in Chile.EDUARDO GARCES/EUROPEAN SOUTHERN OBSERVATORY

A web of steel girders is rising from the flattened summit of Cerro Armazones, 3000 meters above sea level in Chile’s Atacama Desert. The dome it will support will be vast—with a footprint as big as a soccer field and almost as tall as the Statue of Liberty— and unexpectedly nimble: It will smoothly rotate on rails as a giant telescope inside tracks stars through the night.

Everything about the aptly named Extremely Large Telescope (ELT) inspires awe. Its main reflector will be a bowl of silvered glass 39 meters across—the size of three IMAX screens—and the patchwork of 798 hexagonal mirror segments that comprise it must together form a perfect parabola down to a few tens of nanometers. The biggest optical telescope ever built, it will take pictures of Earth-like worlds around others stars and look for signs of life in their atmospheres.

A few months ago, the European Southern Observatory (ESO), which is building the $1.5 billion telescope, declared that construction had passed the halfway mark. Next month, the first batch of polished mirror segments should set off from France by ship in a temperature-controlled container. “It really is going to happen,” says astronomer Richard Ellis of University College London.

As ELT marches toward completion in 2028 or 2029, U.S. astronomers can only look on in envy. A pair of similarly ambitious U.S.-led projects—the Giant Magellan Telescope (GMT) and the Thirty Meter Telescope (TMT)—once vied with ELT to be first on the sky. Although the projects are also polishing mirrors, they have not begun construction—and success is not assured. Unable to find enough funding from private and international sources, they are waiting for the National Science Foundation (NSF) to bail them out by paying at least 25% of their combined cost of about $5 billion. Earlier this month, NSF Director Sethuraman Panchanathan, speaking to a Senate committee, said the agency was looking to make a budget request for construction funding— but not until fiscal years 2025 or 2026. “There is some urgency,” says John O’Meara, chief scientist of the W. M. Keck Observatory. “They need investment by NSF to move forward or the projects are in serious jeopardy.”

ESO, with 16 member nations and a treaty that guarantees steady annual income, can pay for ELT without serious sacrifices, although a few years ago it had to shrink the mirror from an originally planned 42 meters. But for TMT and GMT, led respectively by the California Institute of Technology and the University of California and by the Carnegie Institution for Science, it’s been a struggle. Fundraising has stalled even though the projects have attracted international partners in Australia, Brazil, South Korea, Japan, India, Canada, and China. Ellis, a former TMT board member, thinks it was unrealistic for private institutions to think they could manage multibillion-dollar projects. “This is well beyond any individual university or consortium,” he says.

The two projects acknowledged as much in 2018. Burying the hatchet after years of competition, they joined forces to propose that NSF take a share in the two telescopes, giving publicly funded U.S. astronomers access. In 2021, that proposal, dubbed US-ELT, was named the highest priority in ground-based astronomy by the field’s “decadal survey,” a community exercise that is meant to guide NSF and Congress.

Both projects passed NSF’s preliminary design review earlier this year. But that is just the first of many hurdles. Next week, an NSF panel will assess whether the projects are ready to move to final design and will make a recommendation to Panchanathan. Only after the projects are in the final design stage will NSF consider requesting construction funding from Congress.

Even for the U.S. government, the ask may be too big. Just one of the telescopes would be NSF’s biggest ever outlay for a facility, and Ellis isn’t sure NSF’s astronomy division can convince others that contributing to both at a cost of well over $1 billion is justified. Another problem is operating costs, which at NSF come out of the same account as grants to researchers. Funding one-quarter of US-ELT’s day-to-day operations—likely to be more than $100 million annually—would create a painful squeeze for the astronomy division. Ellis thinks NSF’s slowness to act is a sign of reluctance. “After 2 years there’s nothing to show,” he says. “It would be a tragedy for U.S. astronomy if they don’t get built.”

In the case of TMT, there is an added complication. TMT’s chosen site, near the summit of Mauna Kea on Hawaii’s Big Island, has been opposed by local people including Native Hawaiians who want no more telescopes built on what they consider a sacred place. Protesters blocked an attempt to begin construction in 2015. A second attempt in 2019 was also stymied after protesters built a camp along the summit access road.

Now, says TMT Executive Director Robert Kirshner, “We’re doing a lot of community work in Hawaii. … We have to find a solution that is agreeable to everyone.” NSF, too, is legally required to assess the project’s environmental, historical, and cultural impacts before endorsing it. Officials held public meetings on the Big Island in the summer of 2022, some marked by fractious debates. The agency is now evaluating what it learned. Linnea Avallone, NSF’s Chief Officer for Research Facilities, says the process will take 2 years to complete.

German company Schott has cast glass “blanks” for the Extremely Large Telescope’s 798 hexagonal mirror segments.SCHOTT/EUROPEAN SOUTHERN OBSERVATORY

TMT and GMT continue to work with what funding they have. Three of GMT’s seven 8.4-meter mirrors are finished, three are awaiting polishing, and technicians at the University of Arizona last month loaded 20 tons of glass into a circular mold to cast the last one. The glass will be heated gradually to 1165°C while slowly spinning to give the mirror its parabolic shape.

At the GMT site at Las Campanas Observatory in Chile the seven mirrors will be combined to form a 25.4-meter main reflector. It will give GMT a wide field of view, perfect for surveys, says Chief Scientist Rebecca Bernstein. “Some kinds of science need to get large numbers of objects very efficiently,” she says. The support structure for this mirror is fully designed, Bernstein says, and the team is preparing to begin construction.

Like ELT, TMT will consist of a mosaic of smaller mirrors, an approach pioneered on the existing 10-meter Keck telescopes. At the Richmond, California, plant of the company Coherent, an assembly line is polishing three 1.5-meter mirrors each month before trimming them into hexagons. While Coherent is making 230 mirror segments, other teams in India, China, and Japan will produce the remainder of TMT’s required 492 (plus 80 spares). Kirshner says 97 are done so far. Canada is poised to build the telescope’s enclosure and Japan has committed to building its support structure—once the site dispute has been settled.

ELT has had hiccups of its own. The €400 million contract for its structure and enclosure—the biggest ESO has ever awarded—went to a consortium of two Italian companies, Astaldi and Cimolai. When Astaldi went bankrupt in 2018, Cimolai had to take over, which led to delays that ESO says it has recovered from. French company Safran-Reosc is producing up to four mirror segments a week at a dedicated factory in Poitier and is ramping up, says ELT program manager Roberto Tamai. Once the first 45 have passed inspection, they’ll be packaged up and dispatched to Chile. Tamai says: “Now you can touch with your hand things that were only on paper for so many years.”

Quelle: AAAS

----

Update: 22.02.2024

.

Giant Magellan Telescope Expands Global Science Impact with Taiwanese Partner

Through ASIAA, Taiwan joins Australia, Brazil, Chile, Israel, South Korea, and the United States in building one of the world’s largest and most powerful telescopes

The Giant Magellan Telescope today welcomes Academia Sinica Institute of Astronomy and Astrophysics (ASIAA), a distinguished Taiwanese research institute, into its international consortium. ASIAA’s inclusion expands the consortium to 14 international research institutions, underscoring Giant Magellan’s significance to the global astronomy community and the consortium’s commitment to prioritizing global collaboration for the advancement of science.

“We are thrilled to welcome ASIAA into our international consortium of distinguished partners,” said Dr. Walter Massey, Board Chair of the Giant Magellan Telescope. “Together, our consortium combines worldwide science expertise and engineering acumen to create a project that benefits all walks of research relating to the universe. This collective investment in the Giant Magellan Telescope is a testament that science can transcend boundaries and bind humanity together for good.”

The astronomical research and instrumental development capabilities in Taiwan have received international recognition. ASIAA will contribute expertise in areas such as low noise and compact detector electronics, precision detector characterization technology, precision laser cutting technology, and many others. These contributions will prove invaluable once the telescope is commissioned in the early 2030s.

“ASIAA is delighted to be a part of the Giant Magellan Telescope consortium, and the Taiwanese scientific community is prepared to contribute its expertise while also benefiting from the wealth of knowledge within the consortium,” said Dr. Ue-Li Pen, the Director of ASIAA. “Joining one of the thirty-meter-class telescopes has been a long-term aspiration for Taiwanese astronomers, and Giant Magellan is considered the most suitable project for this endeavor. The collaboration between ASIAA and the Giant Magellan Telescope establishes a robust foundation for astronomical research in Taiwan, with a particular emphasis on nurturing the development of new generations in the field. We also anticipate that this project will deepen collaboration between Taiwan and the six other countries in the consortium.”

Construction of the telescope advances rapidly in the Chilean Atacama Desert and in labs around the world. Over the past year, fabrication commenced on the seventh and final primary mirror in Arizona, while manufacturing of the 39-meter-tall mount structure began in Illinois. Progress includes completion of the first of seven mirror covers in Germany, and near completion of the telescope’s first adaptive secondary mirror in France and Italy. Other advancements were made on a suite of high-resolution imagers and spectrographs in Arizona, Australia, California, Massachusetts, South Korea, and Texas.

These optical technologies will enable the Giant Magellan to boast a remarkable tenfold increase in resolution compared to the Hubble Space Telescope and deliver up to 200 times the power of today’s best telescopes. The breakthrough technologies will empower scientists worldwide, offering unparalleled insights into the evolution of the universe, the origins of chemical elements, and the discovery of life on distant exoplanets for the first time.

News of ASIAA’s inclusion into the Giant Magellan Telescope’s international consortium was celebrated by elected officials in the United States dedicated to scientific advancements, democratic values, international partnerships.

US Senator of Arizona and former NASA Astronaut Mark Kelly emphasized how science collaborations can strengthen international relations. “Arizona has long been a leader in astronomy and optical research, and thanks to key contributions from the University of Arizona and Arizona State University, the Giant Magellan Telescope will lead the way making the next generation of discoveries in astronomy,” said Senator Kelly. “We welcome the newest collaborators from Taiwan to the Giant Magellan consortium and look forward to strengthening ties between Arizona and Taiwan through our shared commitment to democracy, education, and innovation.”

US Congressman of Texas and Chairman of the House Committee on Foreign Affairs Michael T. McCaul, also emphasized the significance of supporting large international research initiatives. “I’m glad our friends in Taiwan have joined this important project, which includes top-notch research institutions like Texas A&M and The University of Texas,” said Congressman McCaul. “The Giant Magellan Telescope will be a ground-breaking observatory that will expand our knowledge of the universe and enable the US to maintain its dominance in ground-based optical and infrared astronomy.”

ASIAA joins Arizona State University, Astronomy Australia Ltd., Australian National University, Carnegie Institution for Science, Harvard University, Korea Astronomy and Space Science Institute, São Paulo Research Foundation, Smithsonian Institution, Texas A&M University, The University of Texas at Austin, University of Arizona, University of Chicago, and the Weizmann Institute of Science in building the Giant Magellan Telescope.

Quelle: GMTO Corporation

----

Update: 2.09.2024

.

Giant Magellan Telescope Mount Fabrication Begins

Ingersoll Machine Tools Inc. builds the largest telescope mount manufactured in the United States

The Giant Magellan Telescope and Ingersoll Machine Tools Inc. today announced the start of manufacturing and assembly of the largest telescope mount built in the United States. The 39-meter-tall precision moving structure was developed in partnership with OHB Digital Connect. In 2022, Ingersoll finalized its 40,000-square-foot manufacturing facility expansion, equipping it with the nation’s newest and largest gantry mill to construct the mount. Once assembled, the mount will undergo performance testing before being shipped nearly 6,000 miles to the Giant Magellan Telescope site in Chile for reassembly.

“We are proud to be a part of developing and building the mount structure for the Giant Magellan Telescope. Ingersoll’s rich history of building very large, complex, and very accurate machine tools complements the unique design of the telescope and the impressive engineering capability of our partner company OHB in Germany,” said Jeffrey Kimberly, Chief Operating Officer of Ingersoll Machine Tools. “The collective expertise of this entire team is what makes it possible to build this impressive scientific wonder that will lead to new discoveries that are beyond our imagination with today’s current capabilities.”

The Giant Magellan Telescope mount weighs 2,100 metric tons and is designed to support seven of the world’s largest mirrors, adaptive optics, and scientific instruments. Despite its immense size, the mount is remarkably agile, gliding frictionlessly on a film of oil just 50 microns thick, resisting image quality disruptions and allowing it to track celestial objects billions of light years away. The steel structure sits atop a 22-meter-diameter concrete pier that was engineered to protect the telescope during seismic events in the Chilean Atacama Desert.

Producing the mount with such precision involves a large workforce of skilled engineers, designers, and manufacturing professionals across multiple states. Industry leaders and policymakers recently gathered in Rockford, Illinois, part of America’s manufacturing heartland, to tour the new Ingersoll facilities where the mount will be assembled over the next 6 years using steel sourced from the United States.

“The Giant Magellan Telescope is yet another example of why the world looks to Illinois as a leader in research,” U.S. Sen. Dick Durbin (D-IL) said. “This project leverages the expertise of Ingersoll Machine Tools in Rockford with the brainpower of the University of Chicago to study the outer reaches of our universe. In addition to the discoveries that will impact future generations, the project has created jobs right here in Rockford and is an exciting development in astronomy.”

The Giant Magellan Telescope will be 200 times more powerful than today’s best telescopes. This power stems not just from its large 25.4-meter diameter primary mirror array, but also from the synergistic performance of its efficient optical design and advanced scientific instruments. The innovative design makes the Giant Magellan Telescope unique among the new class of “extremely large telescopes” for its ability to deliver the highest performing combination of image quality, field of view, and light sensitivity ever achieved.

“Our cost-effective design enables us to build the Giant Magellan Telescope faster and with less risk, all while achieving the broadest range of scientific capabilities,” said Robert Shelton, President of the Giant Magellan Telescope. “Ingersoll’s global experience in manufacturing giant precision structures has been instrumental on our way to becoming one of the most powerful ground-based telescopes in the world.”

Advancement of mount fabrication marks a major milestone for the Giant Magellan Telescope, now 40% under construction across 36 states and on track to be operational in Chile by the early 2030s.

About Ingersoll Machine Tools

Founded in 1891, since 2003 Ingersoll Machine Tools is part of the Italian holding Camozzi Group, an international player specializing in the engineering and production of high-tech components and solutions for industrial automation. The Group also designs and manufactures intelligent cyber-physical systems, leveraging its longstanding expertise in mechatronics. Additionally, it produces high-tech textile machines, special machine tools and develops advanced solutions for additive manufacturing dedicated to the aerospace, naval, and energy industries.

Since its inception, Ingersoll Machine Tools Inc. has been an iconic name in the milling machines sector, successfully serving the defense and then the newborn aeronautics/aerospace industry. During the 1990s Ingersoll pioneered the automatic fiber placement and the automatic tape laying technologies for composite manufacturing and became one of the leaders for this market. Since 2015, the expertise, methodologies, and techniques acquired in developing composite manufacturing have served as an extraordinary technological springboard that allowed Ingersoll to enter the additive manufacturing sector and to immediately diversify from the competition with its offer of wide-and-high 3D printers (MasterPrint®) that completes and complements its composite and subtractive products portfolio.

About Giant Magellan Telescope

The Giant Magellan Telescope is the future of space exploration from Earth. Using seven of the world’s largest mirrors, the 25.4-meter telescope will produce the most detailed images ever taken of our Universe. It will uncover the cosmic mysteries of dark matter, investigate the origins of the chemical elements, and search for signs of life on distant planets. The Giant Magellan Telescope is the work of the GMTO Corporation, a 501(c)(3) nonprofit and international consortium of 14 universities and research institutions from the United States, Australia, Brazil, Chile, Israel, South Korea, and Taiwan. The telescope is being built in America and will be reassembled and completed in Chile by the early 2030s.

Quelle: Giant Magellan Telescope