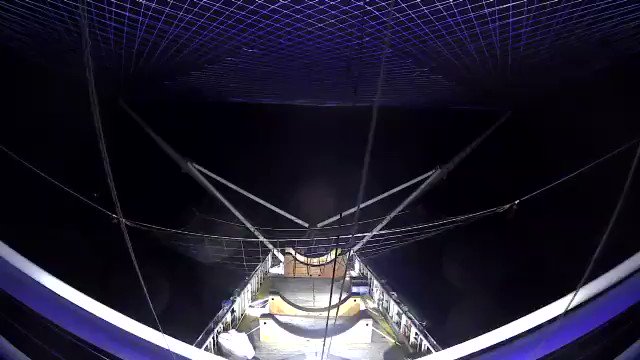

View from the fairing during the STP-2 mission; when the fairing returns to Earth, friction heats up particles in the atmosphere, which appear bright blue in the video

5.07.2019

SpaceX and CEO Elon Musk have released videos offering an extended look at the unexpectedly dramatic conditions Falcon payload fairings are subjected to during atmospheric reentry, as well as the first successful landing in GO Ms. Tree’s net.

Captured via an onboard GoPro camera during Falcon Heavy’s June 25th launch of the USAF Space Test Program-2 (STP-2) mission, the minute-long cut shows off a light show more indicative of a spacecraft entering hyperspace than the slightly more mundane reality. Shortly after SpaceX posted the reentry video, CEO Elon Musk followed up with a video showing a fairing’s gentle landing in Ms. Tree’s net. More likely than not, the fairing with the camera attached and the fairing that became the first to successfully land in Mr. Steven’s (now GO Ms. Tree’s) net are the same half. Regardless, the videos help document a major step forward towards SpaceX’s ultimate goal of fairing reuse.