22.03.2019

Boeing reaches long awaited SLS engine section milestone as NASA makes EM-1 2020 schedule push

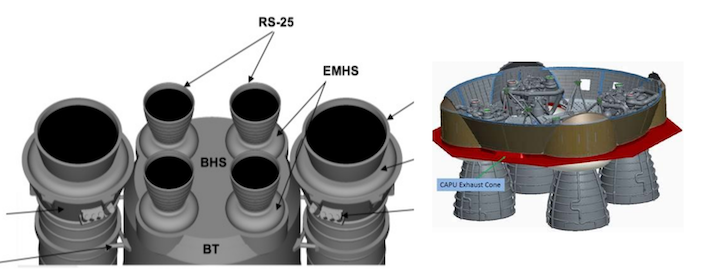

Space Launch System (SLS) Core Stage prime contractor Boeing reached a long-awaited milestone this week with completion of standalone work on the engine section for the first vehicle. The most complex section of NASA’s new rocket stage is well behind more than one schedule revision, and because it is the critical path in the schedule the delays have pushed some estimates for the vehicle’s first launch into 2021.

While the element proceeds immediately into the next phase of integration and testing with its boattail, a series of reviews of Core Stage production are being conducted by upper NASA management to speed up the schedule. Following last October’s Inspector General report, independent consultants were brought in to help with an internal assessment of how to address the report’s recommendations.

After NASA recently concluded the June, 2020 launch date commitment for Exploration Mission-1 (EM-1) was not achievable, one study was started to look at replacing SLS on EM-1, while additional reviews were started to look for more aggressive ways to compress the SLS schedule to its first launch.

Standalone engine section work completed

The engine section was moved on March 20 from its integration area in Building 103 at the Michoud Assembly Facility (MAF) in New Orleans to the adjoining Building 110, also known as the Vertical Assembly Building (VAB). The long-awaited move came after the completion of a significant phase of assembly, where all the equipment, wiring, tubing, and insulation internal to the element was installed.

There is still more integration and testing to do; the next step is to bolt the boattail assembly on the bottom, connect up additional systems, and begin a series of functional tests of the mated combo. The boattail assembly is a streamlined extension for the bottom of the engine section and also includes a downward-facing base shield that provides protection from the heat generated during launch and ascent.

As more and more of the equipment was put in place in the aft compartment of the stage, the confines of the controlled work area got more constricted. “That becomes increasingly a bigger challenge because the more stuff you put in the engine section the more torturous path it is for people to get in there,” Pat Whipps, NASA’s SLS Stages Office Resident Manager at MAF, said during a February 28 media event there.

“We used to be able to work on four levels at once and now you’re down to only a dozen people. It may get even less than that, but you still want to be as efficient as you can.”

Just about the last hardware to be installed inside were the avionics boxes that work with the vehicle flight computers elsewhere on the stage to control things like propellant and pressurization flows, hydraulic systems, and thrust vector control hardware. Most of the work in the weeks leading up to completing standalone integration was testing all the installed hardware.

All the wiring routed inside the engine section had to be tested to verify its continuity after installation. Once orbital tube welding was completed to seal the different systems, they all had to be tested.

“Right now as I speak we’re in the engine section doing ninety leak check points on the helium LH2 system that’s inside the engine section,” Myron Fletcher, Boeing SLS Propulsion Engineer, said at the late February media event. “It’s maybe a mile of tubing that we’re doing leak checks on today.”

“We put a pressure on the system and we do what we call a helium sniff test using a mass spectrometer. You take that mass spectrometer around to every single joint and we calculate the leakage rate around every single joint based on our background.”

Final applications of foam insulation for a few of the sections of cryogenic ducting inside were held until traffic from technicians working in areas around them subsided. 3-D printed molds are placed around parts with complex geometries and the foam is poured into them to cure.

Agency looking aggressively to fly EM-1 in 2020

The engine section continues to be the pacing item in the schedule to complete assembly and testing of Core Stage-1 (CS-1), the first flight unit. It has taken much longer than expected to get to this point, delaying downstream work and pushing estimates of when the overall SLS rocket will be ready for its first launch into 2021.

With the Administration’s desire to fly the EM-1 test flight before the end of 2020 and a recent internal assessment concluding that the stage’s integration and test schedule wouldn’t support that, the agency is aggressively looking for new options to get back on schedule. The first new option discussed in public was a study to assess the feasibility of using commercial launch services to launch EM-1 instead of SLS, but NASA is also looking at new options to shorten the SLS schedule.

NASA’s periodic assessments had shown that the schedule was sliding not long after the last baseline commitment for EM-1 was announced in November, 2017; however, new assessments of the SLS Core Stage schedule began in October in response to recommendations from an audit by NASA’s Office of Inspector General (OIG). The report was publicly released on October 10, but a draft was sent to Human Exploration and Operations Mission Directorate (HEOMD) management in late August for review.

OIG made seven recommendations to HEOMD covering Core Stage production generally and Core Stage-1 specifically; HEOMD Associate Administrator Bill Gerstenmaier’s early October response was included in the final report.

The Congressional submission of NASA’s FY 2020 budget proposal released on March 18 highlighted the schedule-related aspects of the response as the Administration also looks for ways to accelerate the SLS schedule for EM-1. “In October 2018, the SLS program began an assessment of core stage production,” the report says.

“The assessment included representatives with experience in aerospace manufacturing and covered production schedule risks, risk mitigation approaches in work, and recommendations for additional schedule risk mitigations and corrective action and was presented to HEO (Human Exploration and Operations) in February 2019.”

“On March 4, 2019, HEO chartered an assessment of other activities planned to achieve a launch in 2020,” it adds. “Specifically, this assessment will evaluate alternate approaches for hardware processing and facilities utilization for key components.”

“The goal of this activity is to maintain an early as possible launch date.”

The budget submission noted this second assessment was scheduled to be completed on April 15. Focusing on schedule, an obvious candidate for an “alternate approach” is the Stage Green Run test campaign long in planning for the Stennis Space Center.

The Green Run campaign was planned both to acceptance test the stage and verify Boeing and NASA’s analytical modeling of how the rookie SLS stage performs with veteran Space Shuttle Main Engines, now called RS-25s. Core Stage-1 is the first working stage article, and six months was allocated in the schedule to run the stage through activities being performed for the first time in the program, such as cryogenic propellant loading, and a full, eight-minute flight duration firing.

Eliminating the Green Run testing (which could take longer than estimated), skipping the trip to Stennis, and taking the new stage directly to Kennedy Space Center would significantly compress the schedule. Prior to completion of the OIG audit, NASA had studied substituting a brief, five-second static fire of the Core Stage on the launch pad at KSC for the eight-minute long full duration firing at Stennis; the stage would be stacked with its SLS Boosters on the Mobile Launcher for the test, also referred to as it was in the Space Shuttle Program as a Flight Readiness Firing (FRF).

Although an FRF may not completely achieve Green Run development objectives, it would significantly improve the schedule. Additional structural dynamics testing in the integrated launch processing schedule could also be traded for more schedule with NASA looking to fly as early as possible.

Following the completion of the second HEOMD assessment, the budget submission noted another review by NASA’s Chief Financial Officer to look for additional ways to speed up the schedule. “After completion of the HEO assessment, an independent schedule risk review led by the NASA Office of the Chief Financial Officer, set to begin mid-April 2019, will assess the proposed new plan to include: the integrated, detailed schedule and associated risk factors ahead of EM-1; considering technical complexity.”

Next steps being rewritten

During much of this first Core Stage assembly and production flow, Boeing and NASA have looked at ways of rearranging the original sequence of tasks to adjust to issues such as development of manufacturing and production processes, establishing a parts supply chain, and qualification of subsystem components. In addition to shuffling tasks, the flow of hardware has also been shuffled through common areas at MAF like the VAB, with Boeing and NASA officials there currently juggling hardware for Core Stage-1, structural test articles, and Core Stage-2.

Since the post-OIG report internal assessment started in October, a number of additional changes were made to the workflow for the remainder of Core Stage-1 assembly, integration, and test. Even before the engine section moved into Cell A, the next sequence of steps was reworked.

“We have procured some new tooling (delivered today and currently being assembled) that enabled a plan to reduce the work scope for the ES/BT (Engine Section/Boattail) in Cell A,” Steven Ernst, Core Stage Engineering Support Manager for Boeing, said in a March 7 email. “The ES/BT will be mechanically mated then moved from Cell A back into Bldg. 103 for the completion of integration and testing.”

The boattail moved into Cell A first on March 19, with the engine section moving into the Building 110 aisle on March 20 to start lifting activities that were underway on March 21. The new tooling allows the mated assembly to be moved and allows for multi-level access platforms to be placed around it; the improved access is expected to allow more work to be done in parallel.

Clearing Cell A also allows final assembly of the fourth and final structural test article for the liquid oxygen (LOX) tank to be completed in parallel with the first part of engine section functional testing. Stacking of two simulators to the LOX tank qualification article needs time in both stacking cells in Building 110.

Additional wire harnesses and tubing need to be connected between the engine section and boattail after they are bolted together in Cell A and moved back into Building 103. Functional testing of all the engine section equipment is done in parts.

“So we go into Cell A, we’ll stack with boattail, we have some integration to do once we have boattail on and once we get that complete we’ll be able to do a portion of the functional testing for engine section,” Jason Grow, SLS Core Stage Lead Propulsion Engineer for Boeing, said.

“After that portion is done we’ll bring hydrogen tank on, after the hydrogen tank is on, we have a little bit more integration to do and then we’ll be able to finish out functional testing.” The baselined aft join mates the boattail to the bottom of the engine section and the liquid hydrogen (LH2) tank to the top.

The LH2 tank is currently in the Final Assembly area for the current round of standalone integration work. With extra time due to the delayed completion of engine section, work to attach the two feedlines that run down the outside of the LH2 tank was moved up. The work is normally baselined for Final Assembly, the last part of the production sequence.

All of the testing and checkout requirements to complete assembly of the stage will be met, but with the extra oversight of production still more changes to when and where work is performed are expected.

Quelle: NS

----

Update: 27.03.2019

.

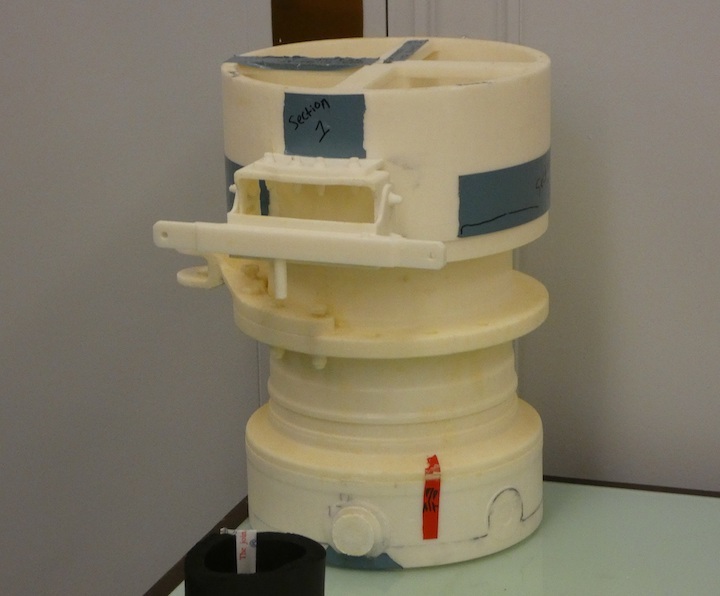

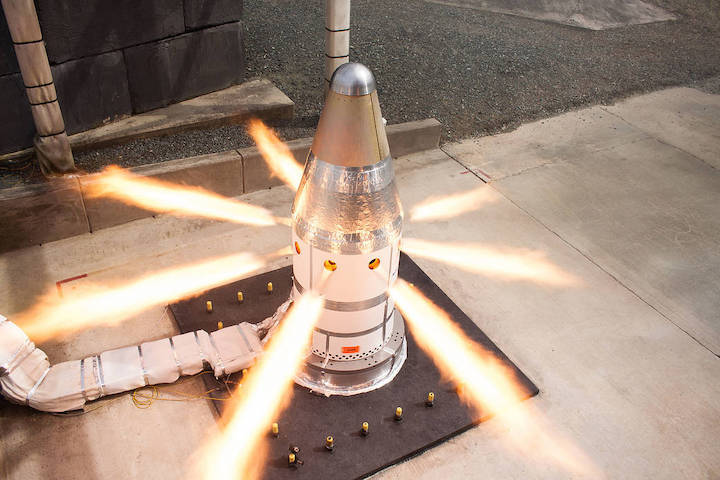

Orion Launch Abort System Attitude Control Motor Hot-Fire Test

Engineers conducted a static hot-fire test of the Orion spacecraft's Launch Abort System Attitude Control Motor at a Northrop Grumman facility on March 20, 2019 in Elkton, Maryland. The 30-second test is one in a series of three tests aimed at qualifying the motor for human spaceflight, to help ensure Orion is ready from liftoff to splashdown for missions to the Moon.

Image Credit: Northrup Grumman

+++

Quelle: SN

+++

Concerning Orion – Amid SLS push, Orion requires Life Support testing

While NASA pushes it Space Launch System (SLS) to make a mid-2020 debut, Orion also needs to find solutions to both match the realigned targets and achieve key objectives before the second flight with astronauts onboard.

Most notably, the Orion Environmental Control and Life Support System (ECLSS) is set to make its full debut on the first crewed mission, requiring the spacecraft to loiter in Low Earth Orbit (LEO) – before heading to the Moon – to allow for a speedy abort should issues be found in the system. Various test opportunities, including on the ISS, are being called upon to mitigate potential issues.

Exploration Mission -1 (EM-1) will be an uncrewed test flight paving the way for the crewed EM-2. However, EM-1’s Orion will not fly with a complete life support system.

This has been a concern for NASA’s Aerospace Safety Advisory Panel (ASAP)for some time, resulting in calls to mitigate the potential the system could suffer a mission-ending fault during the following flight, EM-2.

“In its 2018 Annual Report, ASAP expressed concern about the readiness of the ECLSS for crewed flight – more specifically, whether it would be fully tested, qualified, and ready to support the crew on EM-2,” noted the minutes from the latest ASAP missing in March.

“Because of the crucial importance of ECLSS function for successful crewed flight, ASAP had asked earlier for more information on the ECLSS systems or components that would actually be installed in EM-1.”

NASA had already provided the rationale for not flying EM-1 as a full-up test of the ECLSS, noting “the Orion System is much simpler than that of previous vehicles” and “the spaceflight environment would not significantly impact system performance compared to what is seen during ground testing”.

It also inserted a 24 hour checkout period for the EM-2 flight, allowing Orion to remain in Low Earth Orbit (LEO) for around a day to checkout the health of the ECLSS, before deciding if to abort the mission or press on to the TLI (Trans Lunar Injection) burn and head towards the Moon. This objective was first recommended back in 2013.

“For these reasons, NASA concluded that no specific element of ECLSS hardware requires successful testing on EM-1 prior to EM-2. This conclusion may well prove to be correct; nevertheless, the Panel believes that the more that critical life-support systems and subsystems can be tested in an end-to-end fashion before they are used in crewed flight, the better,” added the ASAP meeting’s minutes.

The ASAP noted that it recommends that NASA should continue to assess whether additional ECLSS hardware could be incorporated on the EM-1 flight, “if the mission is delayed”, which is somewhat moot given the EM-1 mission is now being told to advance, rather than slip further to the right.

NASA has some very useful experience with life support systems, not least on the ISS which has allowed for a continued human presence in space for many years and the ability to learn techniques to repair and improve the ECLSS.

It is understood that some Orion ECLSS specific hardware has been tested on the ISS and the ASAP encourages further testing to help mitigate any potential concerns with the EM-2 flight.

“…emphasizing that the complete ECLSS system has not yet been tested on the ISS – only similar components, in conditions projected to be relevant to the new spacecraft, the Panel again emphasizes the value of end-to-end microgravity testing of the ECLSS system prior to EM-2,” added the ASAP minutes.

Orion itself is no longer the critical path on NASA’s EM-1 timeline, which has since been overtaken by concerns with the Space Launch System (SLS) flow, notably the core stage. Previously, Orion – specifically the European Service Module (ESM)– was the critical path that was threatening additional delays to the EM-1 timeline.

Orion will still need to be on its guard if it is to avoid becoming the schedule concern, should SLS find a way to viably target mid-2020, as instructed by the NASA Administrator Jim Bridenstine. As such, it has already looked into a plan to allow for several months of schedule mitigation.

One such option would be to skip most of the Orion fueling tests at the MPPF (Multi-Payload Processing Facility).

The thought is that KSC could save six months of schedule by skipping all the hypergolic loading and unloading testing now scheduled for the Orion stack in the MPPF.

Thus Orion would go from the O&C (Operations and Checkout Building) to MPPF, be fueled, then go to the VAB (Vehicle Assembly Building) for stacking on the SLS.

Such a change to save schedule would likely be a last-ditch measure should Orion become the critical path again, given once Orion is fueled, it can not go back into the O&C in the event of a problem – such as contamination being found – until it is defueled and decontaminated of all hypergolic fuel traces and would require remedy outside the O&C building.

The next major test objective for Orion will be the Ascent Abort -2 test (AA-2), which is now Range Approved for launch on a Minotaur IV booster from Cape Canaveral’s SLC-46 on June 12 during a four hour window opening at 11:00 UTC.

Quelle: NS

----

Update: 5.04.2019

.

More Delays Ahead for Boeing's New Space Capsule for Astronauts

One of Boeing Co's CST-100 Starliner astronaut capsules is seen at a production facility in Cape Canaveral, Florida, Jan. 15, 2019.

CAPE CANAVERAL, FLORIDA —

Boeing's new space capsule for astronauts faces more launch delays.

The Starliner capsule was supposed to make its debut this month, after a series of postponements. But the first test flight is now off until August. And the second test flight, with astronauts, won't occur until late in the year.

NASA announced the revised lineup Wednesday. At the same time, officials said the first Starliner crew will remain at the International Space Station longer than the few weeks originally anticipated. The mission length will be decided later.

SpaceX, NASA's other commercial crew provider, successfully flew its new Dragon capsule without a crew to the International Space Station last month. The first flight with astronauts could be as early as this summer, but the schedule is under review.

Boeing said the last major milestones have been cleared and the capsule is almost finished. But scheduling conflicts with an early summer Air Force launch helped push the Starliner's debut into August.

The Starliner will fly on United Launch Alliance's Atlas V rocket, the same kind of rocket needed for the Air Force's critical mission in late June, from the same pad.

While the first SpaceX astronauts will visit the space station for a few weeks at most, the Starliner's three-person crew will move into the orbiting complex for an extended period. The typical station stay is about six months.

NASA wants to reduce its reliance on expensive Russian Soyuz capsules as soon as possible, and so the Boeing test flight will double as a taxi mission for station residents. NASA astronauts have been riding Russian rockets since the end of the space shuttle program.

SpaceX Dragons and Boeing Starliners will return human launches to Florida, following the eight-year hiatus. NASA contracted with the two companies to handle space station ferry flights, so it could focus on getting astronauts to the moon and, eventually, Mars.

Quelle: VOA

----

Update: 6.04.2019

.

ENSURING NASA’S SPACE LAUNCH SYSTEM HAS THE PROPULSION IT NEEDS

- All 16 RS-25 engines slated for the first four SLS missions have successfully demonstrated flight worthiness.

- All flight controllers for NASA’s first four SLS flights have successfully completed testing.

- The new RS-25 engine controller, which regulates and monitors engine thrust levels, health and performance, has 20 times the processing capability of the shuttle-era controller.

STENNIS SPACE CENTER, Miss., April 4, 2019 – With today’s successful 500-second hot-fire test of Engine 2062 at NASA’s Stennis Space Center, Aerojet Rocketdyne has completed acceptance testing of all 16 RS-25 engines and flight controllers needed to support the first four flights of NASA’s Space Launch System (SLS). The final flight controller was tested on Engine 2062, which is slated to fly on the second mission of SLS, the first crewed mission.

At the conclusion of the Space Shuttle program, 14 of 16 engines in the SLS inventory had previously flown; two new engines were built from spare components. Last year, Aerojet Rocketdyne hot-fired one of the two remaining engines (Engine 2063) that had never flown and, with today’s test of Engine 2062, all 16 engines have completed acceptance testing.

“Generating 512,000 pounds of thrust, the RS-25 engine is a modern marvel, making it the ideal engine to power the SLS,” said Eileen Drake, Aerojet Rocketdyne CEO and president. “We’ve made a major technological leap with modern, upgraded flight controllers; the new controller has 20 times the processing capability of the shuttle-era controller and weighs 50 pounds less.”

The flight controller is a key component of the RS-25 engine; it serves as the brain of the engine and enables communication between the rocket and the engine, relaying commands and transmitting performance data. Additionally, the controller regulates thrust and fuel mixture ratio while monitoring the engine's overall health and status.

All four of the RS-25 engines slated for Exploration Mission-1 are complete and ready for integration into the core stage, as is the RL10 engine used on the rocket’s upper stage. The four RS-25 engines for Exploration Mission-2 are scheduled to be complete in September of this year.

“The excitement is building for the debut flight of SLS,” added Drake. “With today’s test, we are ensuring NASA’s new SLS rocket has the propulsion it needs for future flights carrying humans and cargo to multiple deep space destinations.”

About Aerojet Rocketdyne:

Aerojet Rocketdyne, a subsidiary of Aerojet Rocketdyne Holdings, Inc. (NYSE:AJRD), is a world-recognized aerospace and defense leader that provides propulsion systems and energetics to the space, missile defense and strategic systems, and tactical systems areas, in support of domestic and international customers. For more information, visit www.Rocket.com and www.AerojetRocketdyne.com. Follow Aerojet Rocketdyne and CEO Eileen Drake on Twitter at @AerojetRdyne and @DrakeEileen.

Quelle: Aerojet Rocketdyne

----

Update: 21.04.2019

.

NASA Launch Services Program outlines the alternative launcher review for EM-1

With a mid-2020 Administration deadline for Exploration Mission-1 (EM-1) fast approaching, NASA tasked its Launch Services Program (LSP) to study commercial launch alternatives for sending its Orion spacecraft into lunar orbit on an uncrewed test flight.

Delays in the assembly and test schedule for the agency’s Space Launch System (SLS) booster assigned to launch EM-1 precipitated the start of a flurry of activity in early March to try to find other ways to make sure the mission will liftoff in 2020. Ultimately, SLS won, beating the alternatives – such as a fully expendable Falcon Heavy – as the best option to launch EM-1 per the provided guidelines.

EM-1 is the first Orion solo mission, but its second test flight and many elements of its configuration are already stable. The EM-1 spacecraft is also being closed out for launch ahead of a multi-month test campaign later this year at Plum Brook Station in Ohio, and LSP had to take these factors and more into consideration in looking at the feasibility of the proposal, above and beyond the question of launch vehicle lift capabilities.

The two-week feasibility study had elements that were familiar to LSP, but also ones that were unusual. The June, 2020 launch date, which was NASA most recent official commitment, left very little time to consider anything but current products and services; however, agency leadership has indicated that they are not closing the door on alternatives to launch Orion.

LSP found at least one combination that could be worth further investigation and the Administration may be interested in pursuing development of others.

More time, performance needed

Exploration Mission-1 (EM-1) is currently planned to take NASA’s Orion crew vehicle into a distant retrograde orbit (DRO) of the Moon on an uncrewed test flight, the first in which the spacecraft will fly on its own. The agency’s leadership learned in early March that its most recent launch commitment of June, 2020, could not be met based on SLS schedule estimates at that time.

With some schedule estimates at that point suggesting SLS might not be ready until well into 2021, NASA began looking at all their options to keep EM-1 on a 2020 schedule. One of those efforts was to request that NASA’s Launch Services Program (LSP) evaluate the feasibility of substituting an existing U.S. commercial launcher or launchers to fly Orion on the EM-1 mission.

LSP first heard about the study request from NASA Headquarters in Washington, D.C. on the weekend before the agency’s formal submission of its Fiscal Year 2020 budget proposal on March 11. “I think we first got word of it the weekend of the 9th and 10th of March, so we came in and hit it hard on that Monday,” James Wood, NASA LSP Chief Engineer, said in an April 10 interview.

“Of course we spent a little bit of time over the weekend scoping out how we were going to approach the problem and package it so that we could work it with a small team and work it quietly as we were initially asked to do. We had just spent a couple of solid days working the problem and then the Administrator (NASA Administrator James Bridenstine) I think his first mention of it in public was on the 13th.”

“And so then we said ‘OK, we’re not going to worry about being altogether so quiet now’, but we said we’re going to just keep working this,” he added. “It took right about two weeks before we had something that we were reasonably happy with.”

“We provided the assessment to Headquarters — to HEO (Human Exploration Operations Mission Directorate) and to the Administrator’s office — we provided that, that’s been out-briefed,” Wood noted. “To my knowledge they are still assessing the results and I guess they’re deciding whether or not they want us to do anything additional.”

The study was short, but busy. “We were definitely working it fairly intense,” Mike Carney, NASA LSP Flight Analysis Division Chief, said in the interview. “I wouldn’t say we were working all weekend on it but there were evidently some activities going on over the weekend or in the evenings.”

“Some late day phone calls between us and Headquarters that were happening on a regular basis to just give NASA Headquarters a status where we were with the study,” Carney said.

“It was like having a mission on the West Coast,” Wood added. “Those are the normal hours we keep when we’re launching out of Vandenberg.”

In addition, LSP consulted with the existing NASA programs, Orion’s prime contractor, Lockheed Martin, and commercial launch service providers. “From the flight design/launch vehicle performance perspective, we were working with a couple of organizations outside of Kennedy,” Carney said.

“One was the Johnson Space Center (JSC) Orion folks and of course they had all of the information relative to the Orion mission design and specifics on the lunar injection delta-Vs and the trans-lunar injection (TLI) requirements and we were also working with the Marshall (Marshall Space Flight Center) folks that were tied to the SLS Program that had been working with JSC on Orion.”

“They were familiar with a lot of the launch vehicle performance requirements and constraints and they were helping us just in general understand what we had to do from a performance perspective to satisfy the Orion mission requirements and just again integrate all that together.

“It was definitely a good collaborative effort, we had several just technical telecons between my flight design folks here at KSC (Kennedy Space Center) and then the JSC Orion folks that worked that part of the mission design portion of the problem and then again the Marshall folks that had been helping with the launch vehicle mission design as well.”

“We based our analysis on the change in velocity (typically referred to as delta-V) required to get from low Earth orbit (185 km altitude circular parking orbit is what we primarily used in the study) into lunar transfer orbit,” they said. “That delta-V value is approximately 3.1 km/sec when departing from the 185 km circular parking orbit. In fact, for any low circular parking orbit near this altitude, the TLI delta-V will be approximately 3.1 km/sec.”

Given the current circumstances, none of the launch provider options could close the performance case on its own, and for now NASA is pursuing other options to keep the EM-1 launch targeted for 2020.

Study draws on LSP mission design and integration experience

LSP provides the integration between NASA spacecraft programs and launch services providers like Northrop Grumman, SpaceX, and United Launch Alliance, all the way from selecting a launch vehicle through liftoff and beyond. One of the unusual characteristics of the Orion alternate launcher study was how short a time period was given to look at feasibility.

“When it comes to doing the advanced mission study work and quoting launch vehicle performance, we get asked to do that all the time,” Carney explained.

“It’s primarily through a request that comes from our traditional spacecraft customers, so the science payloads that we work with all the time that have a concept or an idea for a mission. And they’ve got a rough mass estimate and they’ve got some general idea of where they want to go and of course one of the first questions is ‘hey what kind of a vehicle do I need, how big of a vehicle do I need to get this much mass to this orbit?'”

“What you were describing were your daily kind of work in support of announcements of opportunity for a typical science and meteorology type mission,” Wood added. “That’s normal daily business and you’re going to expect that we’re going to have a three or more year integration cycle for any one of those missions.”

“Not only was that [Orion] stack already built — and it’s much heavier than anything we’ve ever carried with one of our mission customers — but then you’ve got the added burden of being able to execute that on a very fixed timeline — like suddenly having a planetary mission pushed onto your plate.”

LSP is managing several existing projects and part of the study was to assess whether they had the resources to add this project with a fast-approaching launch window to their workload.

“One of the things that I thought of as one of the reasons why they asked us to be the ones to look at this, [is] because we’re not just a mission design concept house,” Wood explained. “We only need to look in the mirror to find the guys tasked with doing it and would be finding out firsthand whether or not we had a good idea or not when we said this was feasible.”

“So we looked at this very much from the standpoint of we’re going to be the ones to have to do this, now how are we going to manage it, how are we going to bring this off? And oh, by the way, in 2020 we’ll have missions like Solar Orbiter, Mars 2020 a nuclear-powered rover very similar to the Curiosity rover, and couple of other missions that very much need our full attention,” he added .

“Our Program Manager, Amanda Mitskevich, and her deputy Chuck Dovale, they were very closely engaged with everything that we were doing because we had to work it as a fully integrated team and what resource trades, what schedule trades, and priority trades that we were going to have to make actually bring this off if somebody said ‘OK, you said the idea was feasible, now go do it.'”

Quelle: NS

Fortsetzung SLS Raumschiff ORION Update-38