28.12.2018

SpaceX CEO Elon Musk has suggested that the company’s newly revamped Starship and Super Heavy rocket (previously known as BFR) could perform its first integrated launches – placing Starship into orbit – as few as 12-24 months from today.

Musk indicated that the odds of Starship reaching orbit as early as 2020 are now as high as “60% [and] rising rapidly”, thanks in no small part to the flurry of radical changes the spacecraft and booster have both undergone over the course of 2018.

Combined with a decision – made public at a September 2018 media event – to delay the debut of a vacuum-optimized upper stage Raptor (RVac) and stick with its mature sea level variant, Musk apparently is quite confident that these dramatic shifts in strategy will allow SpaceX to aggressively slash the development schedules of its next-gen launch vehicle. Intriguingly, Musk noted that while these “radical” design changes were almost entirely motivated by his desire to expedite the fully-reusable rocket’s operational debut, it apparently became clear that the cheaper, faster, and easier iteration could actually end up being (in Musk’s own words) “dramatically better” than its exotic carbon-composite progenitor.

BFS arrives at Mars. (SpaceX)

“DELIGHTFULLY COUNTER-INTUITIVE”

Let there be little doubt – I am still immensely skeptical of this radical redesign and the implausible logistics of conducting said redesign at the last second while somehow maintaining the test schedule, let alone expediting it by 6-9 months. Despite the fact that Musk does seem to have a compellingly rational answer to every question thus far asked, he was no less convincing in mid-2016 when he stated with contagious conviction that Tesla’s Fremont factory would be an almost 100%-automated “alien dreadnought” as early as 2018. There is, of course, nothing wrong per se with being wrong, although taking 24 months and several hundred million dollars to realize as much can be downright fatal or at least a major health risk for any given company that faces such a challenge, as was the case with Tesla.

Skepticism aside, there are equally many reasons to be optimistic about the future of SpaceX’s Starship/Super Heavy (BFR) program over the next several years. Not only do metal hot structures have a proven track record of success (admittedly in the 1960s and for suborbital conditions, but still), but the century and a half humans have been making and building with steel serves to aggressively reduce risk in BFR’s development, whereas a giant, highly-reusable spaceship and rocket built mainly out of carbon composites is about as exotic, challenging, and alien as one could muster. One step further, Musk appears to be dead-set on the trade that the benefits of moving from composite to stainless steel far, far outweigh the costs.

Most notably, Musk’s implication that a steel alloy skin – albeit with regenerative (i.e. liquid) cooling – could genuinely stand in for SpaceX’s ablative PICA-X heat shield technology on Starship was the most unintuitive but logical shift yet. Although steel alloys may literally have densities that are significantly higher than carbon composites, composites simply cannot (at least in the current state of the art) withstand high temperatures like those that Starship would inevitably experience during orbital and interplanetary reentries. As a result, Starship would need an extremely advanced heat shield technology that is minimally ablative, extremely lightweight, robust, and shock-resistant, not to mention an additional layer capable of mounting it to Starship’s composite hull while also insulating the propellant tanks and structure from the extreme heat of reentry.

Steel, on the other hand, is one of the least thermally conductive metals available, while also featuring alloys with melting points that can approach and even surpass 1500 degrees C. With regenerative cooling, it’s entirely possible that a hot steel shield and fusion of propellant tanks and load-bearing structures could ultimately result in a spaceship far more reusable, reliable, and perhaps even performant that a spaceship relying on exotic heat shield materials and linerless carbon composite propellant tanks.

Perhaps BFR Block 2 or 3 will make room for dramatically improved composite formulations and production methods down the road, but advanced steel and other metal alloys appear to be the way forward for SpaceX for the time being. For now, we can sit, watch, and wait as something comes together at the company’s South Texas test and launch facilities.

Quelle: TESLARATI

----

Update: 6.01.2019

.

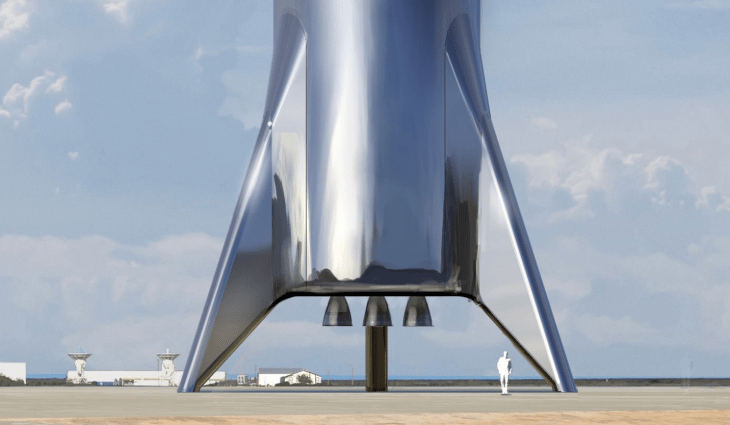

The image here come from Elon Musk and is concept art of the Starship test vehicle SpaceX is currently assembling at its Boca Chica, Texas launch facility. The real thing will be even better. This test vehicle is shorter and lacks the windows of the production ship that will eventually go into production.

This March or April SpaceX intends to launch the rocket to suborbital heights to prove the viability of the Starship’s systems. Orbital flights are said to be on the books for 2020.

The Starship, previously named BFR, is key to the next phase of SpaceX’s plans. The company intends to use this model as its primary launch vehicle, eventually replacing the current Falcon and Falcon Heavy rockets. SpaceX intends to the Starship to be rocket to rule them all. And it’s going to look good doing it.

Quelle: TC

+++

Quelle: Twitter

----

Update: 10.01.2019

.

SpaceX’s Starship reaches new heights as Elon Musk teases Q1 2019 hop tests

In a burst of activity that should probably be expected at this point but still feels like a complete surprise, SpaceX technicians took a major step towards completing the first Starship hopper prototype by combining the last two remaining sections (aft and nose) scarcely six weeks after assembly began.

SpaceX CEO Elon Musk also took to Twitter late last week to offer additional details and post what appears to be the first official render of Starship’s hopper prototype, which is now closer than ever before to looking like the real deal thanks to the incredible drive of the company’s southernmost employees. With the massive rocket’s rough aeroshell and structure now more or less finalized, Musk’s targeted February/March hop test debut remains ambitious to the extreme but is now arguably far from impossible.

Where there was literally just a tent and some construction equipment barely eight weeks ago, SpaceX’s Boca Chica facilities now sport one of the most bizarre developments in recent aerospace history — a vast, ~30 ft (9m) diameter rocket being built en plein air out of tubes and sheets of common steel. At the current pace of work, 24 hours is often enough for wholly unexpected developments to appear, and this Starship hopper (Starhopper) is beginning to look more and more like its concept art as each day passes.

Aside from a few well-earned slow days last weekend, SpaceX technicians, engineers, and contractors have spent the last week or so shaping Starhopper into a form more reminiscent of the conceptual render (clearly hand-painted) Musk posted on Saturday. This primarily involved stacking a tall conical nose section atop a separate cylindrical body section, followed by gradually cladding both the aft section’s legs and barrel in sheets of stainless steel, presumably intended to improve both its aesthetic and aerodynamic characteristics.

Notably, technicians have installed two out of three (?) aerodynamic shrouds at the top of each steel tube leg, bringing Starhopper’s appearance even closer to the smooth and polished aesthetic of its conceptual sibling.

STARHOPPER’S HOPPED-UP HOP TEST ETA

Musk later replied to a question related to Starhopper’s near-term schedule and stated that the nominal target for its first flight test was – almost unfathomably – four weeks away, although he admitted in the same response that that would probably translate into eight weeks due to “unforeseen issues”, placing the actual launch target sometime between February and March 2019. Just to reiterate, the site Starhopper is currently located on was quite literally empty – aside from the temporary tent – in late November 2018, barely more than six weeks ago.

To plan to go from a blank slate to actual integrated flight tests of a rocket – no matter how low-fidelity – that is 9m (~30 ft) in diameter, at least 40m (~130 ft) tall, could weigh as much as 500 tons (1.1M lbs), and may produce ~600 tons (~1.35M lb/f) of thrust at liftoff is extraordinarily ambitious even for SpaceX. At the end of the day, significant delays to Musk’s truly wild timeline are very likely, but it seems entirely possible at this point that Starhopper really could begin its first hop tests in the first half of 2019, kicking off a test program currently aiming for flights as high as 5 km (3.1 mi) and as long as 6 minutes.

A whole range of things will have to go perfectly right for a timeline as ambitious as this to be realized, including but not limited to successfully acceptance-testing three brand new and recently-redesigned Raptor engines, the completion of Starhopper’s unfamiliar structures, propellant tankage, plumbing, and avionics, and the completion of a rough launch and landing pad and integration facilities, if needed. Aside from those big ticket items, many dozens of other smaller but no less critical tasks will have to be completed with minimal to no unforeseen hurdles if hop tests are to begin just a few months from now.

Regardless, SpaceX has pulled off miraculous tasks much like this in its past, and the possibility that the company’s brilliant, dedicated, and admittedly overworked employees will do so again should not be discounted.

Quelle: TESLARATI

----

Update: 11.01.2019

.

SpaceX Finishes Building 'Starship' Hopper Prototype

(Photo)

Credit: Elon Musk/SpaceX via Twitter

SpaceX has built itself a shiny new rocket.

Assembly of the test-flight version of SpaceX's Mars-colonizing Starship vehicle is now complete, SpaceX founder and CEO Elon Musk announced Thursday night (Jan. 10). The suborbital, hopping rocket is a sleek, shiny craft with three prominent fins that end in landing pads.

"Starship test-flight rocket just finished assembly at the @SpaceX Texas launch site. This is an actual picture, not a rendering," Musk said via Twitter. He also posted a photo of the vehicle, which included a spacesuit-clad person for scale.

The construction milestone seems to keep SpaceX on target to begin short "hopping" flights with the prototype vehicle soon. Musk said earlier this week that SpaceX aims to start such trial runs, which will take place at the Texas site near Brownsville, in the next four to eight weeks.

These flights will be similar to those that SpaceX performed in 2012 and 2013 with its Grasshopper test vehicle, Musk added in another tweet Thursday night. The Grasshopper runs, which helped SpaceX get ready to land and re-fly Falcon 9 rocket first stages, reached a maximum altitude of about 2,500 feet (700 meters).

The bona fide Starship will go very far afield, however. SpaceX envisions Starship — which will launch atop a giant rocket called the Super Heavy — taking 100 passengers at a time to and from the moon and Mars, and perhaps other deep-destinations as well. (These names are a recent development. SpaceX had called the reusable rocket-spaceship duo the BFR, short for "Big Falcon Rocket.")

Starship and the Super Heavy will do a variety of other work as well. SpaceX plans to have the duo take over all of the company's spaceflight duties eventually, from launching satellites to supplying and servicing orbiting space stations to ferrying people on superfast "point to point" trips around the globe. SpaceX has already booked the first passenger for Starship, billionaire Yusaku Maezawa, the founder of Japanese e-commerce giant Zozo, for a trip around the moon some time in the 2020s.

SpaceX's Falcon 9 and Falcon Heavy rockets are white, but Starship and the hopper will remain shiny, unpainted metallic silver, Musk has said. But the latter pair will be far from identical. The operational vehicle will have windows, and seven Raptor engines compared to three for the hopper.

And the two vehicles will be different in other ways as well.

"This is for suborbital VTOL [vertical takeoff and landing] tests. Orbital version is taller, has thicker skins (won’t wrinkle) & a smoothly curving nose section," Musk said in another tweet.

The first orbital Starship prototype should be finished "around June," he added in another tweet.

If the testing and development campaign goes well, Starship and Super Heavy could begin flying Mars missions as early as the mid-2020s, Musk has said.

Quelle: SC

----

Update: 12.01.2019

.

Elon Musk says SpaceX has assembled Starship test rocket with shiny, retro look

For weeks, photographers have been snapping pictures of a retro-looking, shiny stainless-steel rocket that’s been taking shape at SpaceX’s launch site in South Texas — and tonight, SpaceX CEO Elon Musk declared that assembly of the first Starship short-hop test rocket is complete.

Musk tweeted a picture of what looks to be a roughly 120-foot-tall “Starship Hopper,” composed of three sections that were put together at SpaceX’s Boca Chica facility.

“This is an actual picture, not a rendering,” Musk wrote. But the rocket does look eerily like the illustration that Musk shared several days earlier — or, for that matter, the pointy-topped rockets that were all the rage in the 1940s.

Starship is the latest incarnation of the spaceship formerly known as the Interplanetary Transport System, Mars Colonial Transporter, the Big Falcon Rocket or the BFR.

Musk says the refuelable Starship, when paired with a huge rocket booster known as the Super Heavy, could be used for transcontinental point-to-point trips on Earth, satellite constellation deployment, voyages around the moon and to the lunar surface, and journeys to Mars and back.

A new type of stainless-steel alloy is being used because that’s the best way for the craft to shed heat as it zooms through the atmosphere. “Starship will look like liquid silver,” Musk wrote.

The craft that has been taking shape in Texas is meant to fly short hops to practice launches and landings, just as SpaceX’s Grasshopper rocket platform and its successor, the F9R Dev, were used as test beds for Falcon 9 booster landings in the 2012-2014 time frame.

Although Musk declared that assembly was finished, there’s more work still to be done. For example, shock absorbers have to be installed on the feet of the landing legs. The engines on the rocket will also be replaced with honest-to-goodness, methane-fueled Raptor engines.

“Engines currently on Starship hopper are a blend of Raptor development and operational parts,” Musk explained last weekend. “First hopper engine to be fired is almost finished assembly in California. Probably fires next month.”

Short-hop tests could begin in February or March. “This is for suborbital VTOL tests,” he said in one of tonight’s tweets. “Orbital version is taller, has thicker skins (won’t wrinkle) and a smoothly curving nose section.”

Musk said he plans to provide a detailed update on the Starship architecture in March or April. The first scaled-up, orbital-class prototype should be done around June, he said.

The aim is to have the Starship and the Super Heavy booster ready for passengers by the mid-2020s, in order to send Japanese billionaire Yusaku Maezawa and an entourage of artists around the moon … and set the stage for Mars trips.

SpaceX has clearly picked up the pace of Starship development in the past month, and the fact that the company is more than halfway through a $500 million funding round could have something to do with that.

It’s interesting that Starship assembly has been taking place outside in full view of SpaceX paparazzi. Here’s a sampling of pictures from the past month:

Quelle: GeekWire

+++

SpaceX CEO Elon Musk says first orbital Starship prototype will be done by June

SpaceX CEO Elon Musk says that the company’s first Starship prototype – a low-fidelity hop test vehicle – has finished assembly in South Texas, paving the way towards a series of experimental vertical take-off or landing (VTOL) hop tests that could begin as early as February or March 2019.

One step beyond the prototype currently rising out of the coastal Texas wetlands, Musk also indicated that the first orbital Starship prototype – essentially the spacecraft’s first full-fidelity test article – could be completed as early as June 2019, a truly extraordinary pace of development for a program as complex and cutting-edge as BFR.

STARHOPPER RISING

Barely six weeks after work began on the massive Starship prototype, SpaceX’s Starhopper appears to have grown to its full ~40m (~130 ft) height in South Texas. Following a preliminary fit test on Tuesday, January 8th, workers made a second attempt on Wednesday and completed the final attachment of Starhopper’s upper and lower halves. Intriguingly, no time was wasted spot-welding the halves together after their successful docking, and an additional sheet of stainless steel has been welded over the seam in the hours since then.

However, what looks like 9m-diameter (~30 ft) steel tank domes are being assembled and welded together at the same SpaceX facility, despite the fact that no domes have been observed being installed inside Starhopper. Musk did seem to indicate that even Starhopper – requiring far less propellant than an orbital Starship – will still feature full 9m (~30 foot) diameter tanks. This could imply that the newly integrated Starhopper has yet to have propellant tank domes installed inside and will need to be taken apart again to allow for that critical final step. If that is not the case, the only possible explanation is that Starhopper’s propellant tanks will actually be less than 9m in diameter and will be lifted up through the vehicle’s aft for installation.

One last increasingly improbable possibility is that a significant portion of the hopper’s upper half will be or already is a pressure vessel capable of holding cryogenic propellant, although the process of actually watching the less than surgical fabrication does not inspire a great deal of confidence in any potential pressure vessel aspirations. In the meantime, we have been given the first look at what the outside of Starhopper will look like once complete. According to SpaceX CEO Elon Musk, hop tests of the imposing vehicle could begin as few as 4-8 weeks from now.

TO ORBIT, AND BEYOND!

Aside from offering the above photo and comparing Starhopper’s prospects to those of Falcon 9’s Grasshopper and F9R hop test articles (i.e. very suborbital and very short-lived), Musk also stated that the first orbital Starship prototype could be completed as early as June 2019, as few as three months after Starhopper’s first hop test. This paints at least a rough picture of the planning going on for BFR’s flight test regime, beginning with a suborbital hop test prototype, moving to a full-fidelity Starship capable of high-speed intra-atmospheric heat shield and aero surface testing, and finally full-up orbital testing with the completion of the first BFR booster (now known as Super Heavy).

According to Musk, the first Super Heavy booster will begin production and assembly as early as spring 2019, while the CEO stated that he believed the odds of BFR (Starship/Super Heavy) reaching orbit by 2020 were 60% and “growing rapidly” thanks to a recent move from carbon composite tankage to stainless steel. If SpaceX and Musk keep putting their money where their mouths are and rapidly building test articles and prototypes, that orbital debut might actually be less insane than it sounds. We’ll find out soon enough.

Quelle: TESLARATI

----

Update: 17.01.2019

.

SpaceX to build Mars ships in Texas, not Los Angeles

SpaceX says it will build test versions of its Mars spaceship in south Texas instead of the Port of Los Angeles, dealing another blow to the local economy only days after the company announced massive layoffs

In this Jan. 12, 2019 file photo, a motorcyclist rides near the SpaceX prototype Starship hopper at the Boca Chica Beach site in Texas. SpaceX says it will build its Mars spaceship in south Texas instead of the Port of Los Angeles, dealing another blow to the local economy only days after the company announced massive layoffs. The Southern California-based company announced Wednesday, Jan. 16, 2019 that test versions of its Starship and Super Heavy rocket will be assembled at its Texas launch facility in a move to streamline operations.

SpaceX said Wednesday that it will build test versions of its Mars spaceship in south Texas instead of the Port of Los Angeles in another blow to the local economy that comes days after the company announced massive layoffs.

The decision was made to streamline operations, the Hawthorne, California-based company said in a statement.

SpaceX won approval last year to lease 19 acres at the port's Terminal Island. It planned to erect a new facility to do work on the interplanetary spacecraft, now called Starship, and its launch vehicle, the Super Heavy, which would be the largest rocket ever built.

The port facility would have allowed the giant craft to be barged or shipped to launch sites. It could have added about 700 jobs to the area.

SpaceX now won't proceed with that option.

SpaceX founder Elon Musk tweeted that development of Starship will continue in Hawthorne but prototypes will be built in south Texas. The company has a launch facility in Boca Chica near Brownsville, where one prototype of the spacecraft already has been assembled.

"We are building the Starship prototypes locally at our launch site in Texas, as their size makes them very difficult to transport," Musk said.

SpaceX will continue using its existing port facilities to recover its reusable Falcon rockets and Dragon spacecraft, which arrive by water.

Southern California officials have talked about luring high-tech operations to boost the waterfront and create a "Silicon Harbor."

"While we are disappointed that SpaceX will not be expanding their operations at the Port of Los Angeles, we are pleased that they will continue their recovery operations here," port spokesman Phillip Sanfield said. "Our ongoing work with SpaceX and other advanced technology companies is important to our efforts to advance the port through innovation and new technologies."

Los Angeles City Councilman Joe Buscaino said he felt crushed by the decision, but "I feel confident that other innovators will see the huge value they get in San Pedro."

Last Friday, SpaceX announced it would lay off 10 percent of its roughly 6,000 workers, most of them at its Hawthorne headquarters. The company said it needs to become leaner to accomplish ambitious and costly projects such as the Starship and Starlink, which would create a constellation of satellites to provide space-based broadband internet service.

Development costs for those two projects have been estimated at up to $10 billion each.

Quelle: abcNews

----

Update: 23.01.2019

.

SpaceX fits Starship prototype with tank bulkheads as hop test pad progresses

SpaceX workers have begun installing fuel and oxidizer tank bulkheads inside the first BFS/Starship prototype at the same time as the vehicle’s nearby ‘launch’ facility continues to sprout important infrastructure and slowly morph from a giant pile of dirt into something capable of supporting rocket hop tests.

Several observable characteristics of this project still do not immediately make sense but whatever the direction SpaceX is moving in, engineers and technicians are working around the clock to ensure that progress is steady.

Moreso than any other single part, the most confusing aspect of Starhopper has to be the apparent condition of its steel tank domes, distinctly covered with a patina of impurities like rust, dirt, dust, and grime. For a water tower or other miscellaneous storage tank, this would be completely acceptable. For aerospace-grade propellant tanks that will have to safely store dozens or even hundreds of tons of supercool liquid methane and oxygen to feed ultra-high-performance Raptor engines, the purity of ingested propellant and thus the cleanliness of the tanks holding it is going to be of paramount importance.

To use an example that applies to the rockets SpaceX currently flies, Falcon 9’s first and second stages are almost always drained and cleaned before and after their first static fire tests in McGregor, Texas to ensure that no unintended debris is ingested by Merlin turbopumps. This is necessary because Falcon rockets are currently built in an extremely large hangar that simply cannot feasibly be kept to cleanroom conditions, while SpaceX’s garment requirements are less strict than some old-guard aerospace companies, typically letting workers wear normal clothes (albeit with hairnets/beardnets) while working inside Falcon 9 tanks and structures. The improved work conditions and worker comfort comes at the cost of frequent tank cleaning.

While SpaceX clearly has a great deal of experience with nontraditional methods of rocket production, the Hawthorne assembly line might be the cleanest cleanroom on Earth compared to Starhopper’s rusty tank domes and fully-outdoors assembly. Even odder is the apparent fact that SpaceX is actually installing (and maybe even welding) those tank domes without any cleaning at all, indicating that they either look far worse than they actually are, are not a real problem for Raptor or cryogenic propellant tanks, or will be scoured only after installation. Regardless, SpaceX is keeping close followers and those familiar with aerospace on the tips of their toes as Starhopper continues to be worked on.

(LAUNCH) PAD PROGRESS

Roughly one mile to the east of Starhopper’s assembly roost, SpaceX employees and contractors have been working to complete earthmoving and start outfitting a prospective Starhopper prototype launch pad with a stable concrete base and all the infrastructure needed to support a complex rocket and its propellant, electricity, and heat-resistant surface needs. However, despite recent statements from executives like CEO Elon Musk and COO/President Gwynne Shotwell, the ‘facility’ appears to be many, many months away from anything reminiscent of an actual launch pad like the three SpaceX currently operates in California and Florida.

Instead, it seems that the first BFR-related launch facility will be more of a Spartan, minimalist slab of concrete, a healthy berm, and a handful of propellant tanks and heat exchangers, much like the ‘pad’ that supported Falcon 9’s Grasshopper and F9R hoppers. Over the last few days, the pad construction crew has installed the first of those propellant tanks and heat exchangers and continue to refine the overall layout of the site, still primarily made of compacted dirt. Given the potential simplicity of a Grasshopper-style launch and landing pad, the facility could be anywhere from a few weeks to a few months away from completion.

Quelle: TESLARATI

----

Update: 24.01.2019

.

Winds in Texas topple top of SpaceX's shiny Starship prototype

The shiny, futuristic SpaceX prototype built to conduct tests of a future company spacecraft fell victim to an unexpected foe Tuesday night: Texas wind.

The "Starship hopper," a small-scale version of the final product designed to take humans on interplanetary trips to the moon and Mars, was damaged when winds broke the secure points for the fairing, or nose cone.

"I just heard," CEO Elon Musk said via Twitter early Wednesday. "50 mph winds broke the mooring blocks late last night & fairing was blown over. Will take a few weeks to repair."

The bottom of the vehicle, which contains propellant tanks and engines, was not toppled or damaged during the windy night. It was expected to launch and land as soon as February, but that will likely be delayed to later in the month or March as teams work on repairs.

The stainless steel craft will only conduct sub-orbital test flights as a way to test systems and engines before building and flying a full-scale model.

The final product will include a "Super Heavy" first stage, which will boost Starship off the launch pad before it embarks on deep-space missions. With a three-leg design, many have compared it to something from a science fiction universe.

SpaceX's South Texas Launch Site near Brownsville hosts Starship hardware and is planned as a future spaceport for the company.

On the East Coast, meanwhile, SpaceX is still targeting February for the launch of an uncrewed Crew Dragon spacecraft from Kennedy Space Center's pad 39A. The company is required to fly a crew-less version before a fully crewed flight, which is currently targeted for June.

Quelle: Florida Today